BATTERY CABINETS

The battery cabinet is a unique sort of safety cabinet intended for use with rechargeable batteries. As the use of batteries in the workplace has increased in recent years, so has the popularity of weatherproof battery box, which offer numerous safety benefits.

The key risks associated include:

- When a battery's stored energy is discharged in an unstable state through a short circuit or for any other reason, an arc flash, higher temperature, or fire may follow, resulting in thermal burns.

- It is possible to get an electric shock from touching the terminals of a series-connected battery.

- Some of the chemicals used in batteries are toxic and corrosive. These can cause severe problems for people and machinery if they leak.

- Chemical burns or shrapnel injuries can result from a battery bursting or exploding owing to gas buildup from overcharging, over-discharging, or a short circuit.

CONSIDERATION OF BATTERY CABINETS

Numerous goods, from forklifts and delivery vehicles to industrial robots and medical gadgets, use rechargeable batteries in the workplace. Almost every sector will use this energy source to power some piece of machinery or technological tool. That's why it's essential to think about how factors like charging and storing your batteries can affect the security of your business.

Controlling a simple system with few batteries within a climate-controlled office may be a breeze. When many batteries are in use at once, however, they may be mishandled or exposed to extreme temperatures and humidity.

Many security measures should be considered when a corporation is storing and charging batteries as part of its normal operations. These include:

- Battery protection against improper use and accidental drops.

- Recognizing and getting rid of worn-out, leaky, or otherwise compromised batteries.

- Keeping batteries in a particular location allows you to keep tabs on your stock and ensures you never run out.

- Preventing overcharging of the battery.

- The battery acid must be contained and cleaned up if it leaks.

Raise in Ambient Temperature

Maintaining a temperature-controlled environment that actively minimizes the likelihood of thermal runaway is among the most crucial factors in battery energy storage systems.

A battery cell enters a thermal overrun condition when its internal temperature rises so that its constituent atoms and molecules decompose exothermically, leading to instability, fire, and explosion.

Even if a single battery can experience thermal overrun, the dangers considerably rise when numerous batteries are kept near one another. When one battery overheats another, thermal runaway can cascade through the system. It makes any fire or explosion involving batteries even more devastating. Therefore, it is crucial to have a properly ventilated and secured battery enclosure for storing and charging batteries at work.

Please pay attention to the manufacturer's guidelines for the batteries you use, as they will provide important information about the risks of using these power sources.

You may want to take the following precautions to reduce potential dangers for your battery cabinet:

- A climate-controlled facility

- Mechanical or natural ventilation

- Fans to circulate heated air

- Stores having a thermal air barrier in their construction

- No exposure to the sun

- Far from hot operations and ignition sources

- Suppression of fires

Since some batteries catch fire while being charged, it's crucial to have a reliable charging station devoid of malfunctions and electrical problems.

The inherent safety of the electrical work used in the construction of battery cabinets lessens the potential risks during the charging process. Look for a battery cabinet that has passed international safety criteria for electrical certification. It will guarantee that your electrical work is up to code with federal or national regulations.

A battery charger that is broken, coiled, or unsafe to use should be avoided at all costs. Check the battery charger's package to ensure it complies with safety laws before installing it in your weatherproof battery box.

Frequent Loss Owing to Theft or Damage of Batteries

Safe and proper battery energy storage system can be easily maintained with the help of battery cabinets. It is less likely that batteries will be misplaced, stolen, damaged, or left in harmful conditions if they are charged and stored in the same place.

Mishandling, charging, and storing batteries can increase risk. Dropping a battery or leaving it in a heated place might destroy the battery cell, causing fire or explosion. By encouraging careful handling and storage, a battery cabinet can reduce these dangers.

Battery cabinets should be prominently labeled with appropriate safety warnings. Putting cautionary labels on your cabinet draws attention to the potentially harmful contents inside, both to employees and emergency personnel.

KEY BENEFITS OF BATTERY STORAGE SYSTEM

- Enhanced power quality and consistent supply to consumers

- Enhanced safety and reliability

- Reduction in noise, vibration, and harshness

- Thermal Stability

- Improved availability

- Improved value of renewable energy source

- Cost reductions through reduced maintenance

Silicon carbide and gallium nitride are two examples of high-voltage, high-power, high-frequency, wide-band-gap materials now being studied in power electronics. Furthermore, continued research and development into enhanced power conversion systems dramatically improve power density and performance of batteries is under observation.

Commercial settings can't function without battery cabinets. Energy load must be balanced using these techniques as the number of energy sources grows. YONGU excels in constructing battery cabinets and other electronics enclosures and understanding the hazards of end-to-end battery energy storage systems.

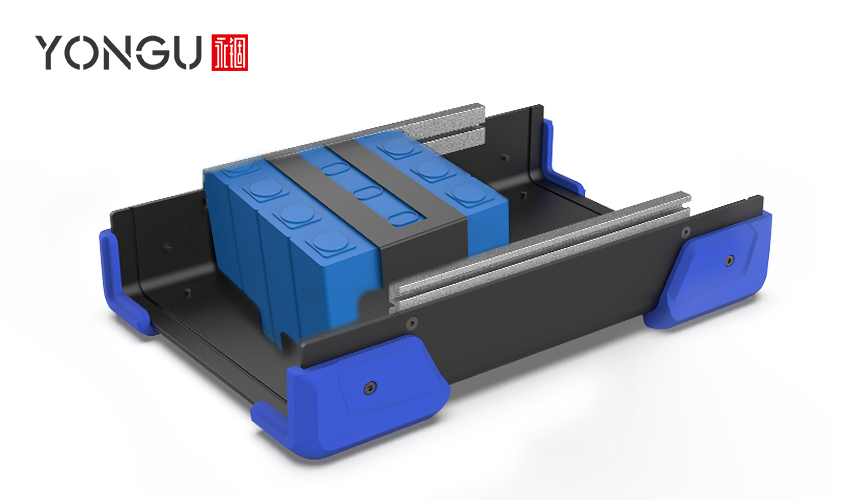

YONGU BATTERY ENCLOSURES

Finding a reliable electronics enclosure manufacturer requires careful consideration of many factors, including the desired enclosure's size, material, rating systems, etc. Knowing the qualities, advantages, and disadvantages of any material is crucial. Our designers and engineers typically choose the components of the aluminum electronics enclosure for battery banks following the required specifications and the unique roles played by the devices.

We are a leading manufacturer of extruded aluminum enclosures for electronic products. Our strength lies in between our three core groups: our designer team, which is well-versed in contemporary design trends; our expert business staff; and our quality control and after-sales service staff. We can use aluminum extrusions in the construction of sleek battery enclosure designs.

Extruded aluminum battery cabinets and enclosures are only some of the many types of boxes available from YONGU.

Typical battery enclosures offered by YONGU include

- YONGU Aluminum Waterproof IP68 Case for Battery M08 110*55 mm

- YONGU YONGU IP67 Power Supply Enclosure L10A 200*150mm

- YONGU YONGU S102 160*60*220 Lithium Battery Box

- YONGU Battery Protection Circuit Housing Split Aluminum Electronic Enclosure H26 143*53.5 mm

They have the following common properties other than meeting international standards

For further information and customized product of your requirements, please follow our FACEBOOK for more updates and informations.

You can also contact us at +86 13326782625 or write us [email protected].

- Two-piece body with easily removable belly plate for easy access

- General Purpose, EMI Shielded with Heat Dissipation Options

- Sandblasted and brushed surface finishing

- Horizontal PCB mounting by sliding into internal slots extruded into the enclosure body

- Customizable length and thickness options

- Rail transit, underwater detection, and outdoor monitoring equipment options

For further information and customized product of your requirements, please follow our FACEBOOK for more updates and informations.

You can also contact us at +86 13326782625 or write us [email protected].