It will be easier to ensure that your enclosure fits your product well, is constructed of the proper materials, has a long life, and complies with the relevant design and safety criteria if enclosure design is included in the early stages of the product development.

Challenges While Designing an Enclosure

Following are some challenges that come across the manufacturers while designing an enclosure.Physical situations:

The internal and external environments provide the experimental results that affect how well a building enclosure performs. In addition, the building enclosure must be built to provide a threshold of control over or resistance to these phenomena to be durable and provide acceptable environmental moderation.Frequency and duration:

Intensity, duration, and frequency are the distinguishing features of all physical occurrences. For example, floods, tornadoes, and earthquakes are events that typically have a high intensity, short duration, and low frequency. Vapor diffusion, heat transfer, and air leakage are low-intensity phenomena with relatively long durations and seasonal periodicity in most temperate zones.Risk of failure:

The risk of failure is the possibility that a particular performance level will be insufficient to resist forced phenomena. However, failure repercussions regarding safety, health, functionality, economy, and beauty must be balanced against the possibility of failure. Through codes and standards, minimum levels of sufficiency for health and safety in buildings have been created, guiding the designer in these crucial facets of building performance.Budget:

On almost every construction job, time and money are major constraints for contractors and their trades. In general, they tend not to invest more time and effort in construction than it is financially worthwhile. For example, ad hoc alterations (also known as cutting corners) may be made by employees trying to achieve productivity requirements if the chosen (often lowest) bidder on a construction project finds an assembly or detail too expensive to execute properly.

Designing enclosures: Important factors to consider

Your electronics equipment will be successful over the long term if you choose the proper box build design. Any industrial electronic enclosure needs to be designed with careful consideration, testing, and planning.Whether your electronic item is wireless industrial control, a piece of medical equipment, or an energy distribution system component, choosing the appropriate enclosure is essential to its success.

Here are the five factors you should look forward to while designing an enclosure.

Choosing the right fit:

Create an enclosure that blends security, usability, affordability, and affordability using 3D modeling. The tooling, materials, and setup costs suitable for your product depend on the intended volumes. The dimensions of your finished product influence delivery costs.It may be more challenging to design suitable housing for a larger gadget. Make sure your device's size and dimensions fit your design-for-manufacturability requirements by working with your design or product development team.

Invest in high-quality material:

Many products that need to be long-lasting and affordable are made of metal, so work with the manufacturer to ensure that your chosen shape is easy to manufacture. Plastic is considerably simpler to shape with proprietary molds and offers corrosion resistance. Your manufacturer may readily customize it to make special shapes. For example, consider keeping with pre-made plastic enclosures that do not require setup fees for lower-quantity designs.Cost, durability, availability, and malleability are the important factors you should consider while choosing the material. Always consider the application of the end user while selecting the material. A robust and impermeable enclosure is needed in numerous settings like outdoors, either underwater, severe temperature, and a lot of moisture.

Ensure proper transmission:

Metal enclosures may prevent wireless signals from being transmitted. Wireless devices are better suited to plastic enclosures, but some wireless devices require a metal enclosure for other reasons, like corrosion resistance.Layout:

Although the product's appearance is not everything, it might matter more than you think. Before making choices that will impact the product's appearance and usage, research the aesthetic practices of competitors in the market. If a branded theme is appropriate for your order volume and something you'd like for your goods, think about it.Customers may prefer small and portable devices or large and difficult to overlook. Recognize your target market and the kinds of things they desire.

Compatibility:

To guarantee package compliance, check your CAD to the BOM (bill of materials). Consider the bill of materials as your supplier's plan for your devices. Verify the entire BOM to prevent communication problems.

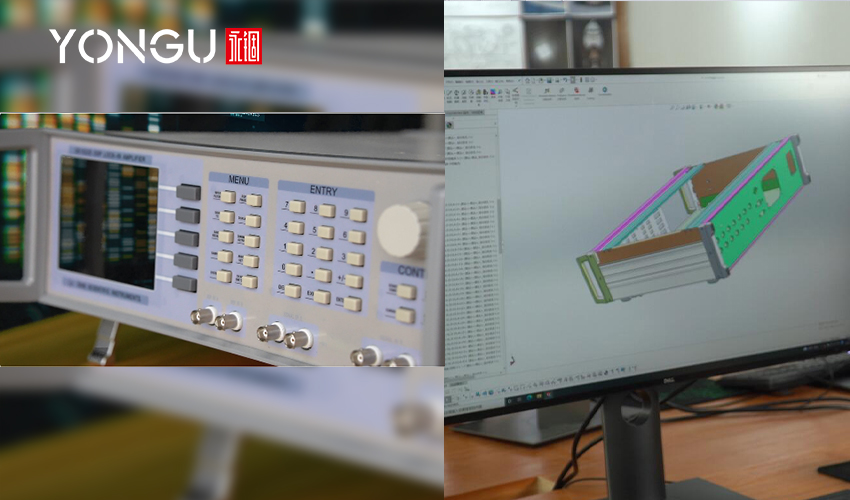

Designing Enclosures with YONGU

It is important to have an effective and trustworthy supplier to prevent disruptions in your supply chain. Yongu Box is committed to providing excellent customer service. You can rely on us to produce your customized enclosure on time and under your requirements. Yongu Box is your best option if you want a full-service supplier of electrical enclosures.Our cutting-edge CNC machines provide the highest design flexibility and cutout accuracy, guaranteeing that your components will fit as intended. High-definition images printed directly onto the enclosures by our digital printers do not peel, bubble, or scratch. Instead, your ordinary off-the-shelf box may become a high-end finished good with precise cutting and superior graphics from Polycase! Our quality and customer service are unequaled due to our quick lead times, lack of minimum order requirements, and years of experience in the electronics/electrical sector.

Conclusion

If any of our enclosures appeals to you but falls short of your demands, we may adjust the design to produce the perfect bespoke solution. Additionally, we work with our clients to develop new solutions tailored to their needs. View a sample of our unique solutions, browse our whole range of engineering and electrical enclosure design services, or get in touch with us for more details.We provide quick and simple customisation options for making unique cutouts and printing on many of our enclosure models. For further information and customised product of your requirements.

For further information and customized product of your requirements, please follow our FACEBOOK for more updates and informations.

You can also contact us at +86 13326782625 or write us [email protected].