Electrical control panels are an integral part of any commercial or manufacturing facility. The electrical enclosure might include a solitary panel or a room full of electrical cabinets.

Considering the high risk of possible fires, automatic fire suppression for electrical panels, switch gears, and infrastructure is critical. They are intended to provide continuous assistance for your business but are frequently overlooked. In a fire situation, not only is the essential operation of the electrical cabinet jeopardized, but it might also spread to neighbouring equipment, inflicting catastrophic damage.

Due to obsolete infrastructure, defective wiring, inadequate maintenance, and overloaded circuits, electrical fires are risk factors. Early identification and suppression of fires to offer quick-fire protection are essential for minimizing fire damage.

VARIOUS TYPES OF FIRE PROTECTION SYSTEMS

The following are the three categories of electrical cabinet and panel fire safety systems:

- Stand-alone systems

- Pre-engineered Systems

- Engineered Systems

FIRE HAZARDS IN ELECTRICAL PANELS

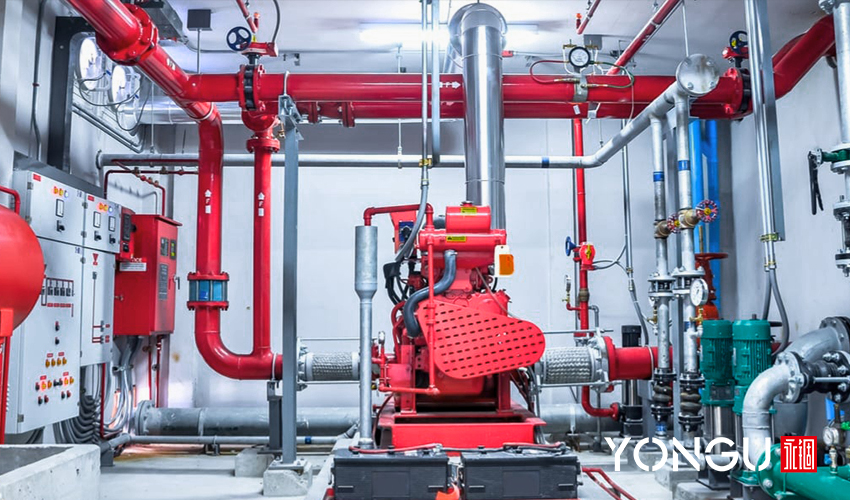

While there are various electrical panels, this provides an overview of how electrical panels appear and work. Electrical panels may be found in almost every manufacturing or commercial facility. The components are usually destroyed if a fire breaks out within one of these panels. If a fire is allowed to burn unchecked, it has the potential to spread across the room or possibly the entire structure.The following are some of the most typical causes of fire in electrical panels:

- Improper setup

- Equipment breakdowns

- Inadequate maintenance

- Circuit overloading

- Arcing electrical current

- Wire deterioration

- Other environmental factors

Let's get into the details of each fire suppression system.

Stand-Alone Fire Suppression System

The terminology "stand-alone fire suppression system" may be a misconception, as it refers to separate devices with fire suppression capabilities that are not connected to a more extensive system. It is made up of similar components as traditional fire suppression systems. The Stand Alone System has a clear benefit due to its compact design. Because no cabling is required aside from the power supply (a hookup to the battery), the following installation is simple and inexpensive.

Stand-alone fire suppression mechanisms function by dispersing the fire suppressor when actuated by heat. All elements of the fire suppression system are incorporated into a single structural unit in this case. The essentials of a standard fire suppression system are the central processing unit, heat detector, fire extinguisher, regulator, and dispersion nozzle.

Pre-engineered Fire Protection System

The second level of protection is pre-engineered fire systems. They are perfect for compact enclosures such as electrical cabinets or precise machinery. These solutions are frequently chosen while examining the various clean agent fire suppression systems. These devices use fire-detecting tubing that bursts when exposed to heat or flames.The cleaning substance is administered directly via the burst aperture in a pre-engineered fire suppression system. Strategically located nozzles distribute the suppression agent in the pre-engineered systems. When a clean agent is used, the fire is extinguished without causing any damage to the electrical components or machinery that are being protected.

Pre-engineered systems are available with a variety of suppression chemicals capable of fighting various types of flames. However, because clean agents leave no residual or inflict damage to electronic systems when the fire suppression system is engaged, pre-engineered systems utilizing cleansing agents will increase uptime.

Engineered Fire Suppression System

A designed fire suppression system provides the maximum degree of protection. When a fire is identified, they are meant to blanket a whole room with a clean agent. Engineered systems are frequently the best solution for rooms with several electrical panels or other infrastructure, such as data centres, that must be shielded from fire and water damage.Instead of water, engineered systems employ non-conductive compounds such as Halon 1211, Bromo Chloro di Fluoro methane, or Carbon Dioxide as fire suppression agents. It is critical in electrical fires because water may harm devices or conduct electricity.

CONCLUSION

When considering the various types of protection mentioned above, selecting the best solution for your environment is critical.

Stand-alone fire suppression systems are an affordable choice for locations with critical electrical cabinets that might not mandate fire suppression but where safety-conscious corporate executives want to add a layer of security for their facility and staff. Engineered systems are the most robust solution for larger setups, while pre-engineered systems perform well for semi-sized rooms with several electrical panels.

YONGU EXPLOSION-PROOF ENCLOSURE

A YONGU explosion-safe electronic enclosure is designed to be corrosion-resistant and to withstand severe temperatures. These flameproof enclosures are an excellent choice for dangerous settings. If you want a high-quality enclosure, look no further than YONGU. High-quality, CNC-precision-cut aluminium is employed to dissipate heat into the surrounding atmosphere.

YONGU offers a unique explosion-proof electronic enclosure, YONGU Split Plastic Pannal Box K20C 150*55mm

It has the following unique features.

- Portable, muti-colour, convenient

- Multi-specification customization

- Crashproof and dust-proof panels

- Integral structure design for Better heat dissipation

- Anti-collision design for better dust-proof

For further information and customized product of your requirements, please follow our FACEBOOK for more updates and informations.

You can also contact us at +86 13326782625 or write us [email protected].