The UL 93 flame scoring system, the most widely adopted industry norm for flame-rated enclosures, is how we grade the flame resistance of our enclosures. This section will cover the fundamentals of UL 93 flame standards and how to interpret them with electrical enclosures.

Manufacturers of electronic components and enclosures can only get UL certification for their products if Underwriters Laboratories has officially evaluated them. To create a worldwide standard that provides customers with an accurate assessment of a product's capabilities, UL maintains exact test conditions and scoring.

For a wide range of industrial and tech product applications, Polycase plastic enclosures are created. There are various advantages to using ABS plastic to create electronic enclosures, including flame-retardant qualities.

Understanding how manufacturers categorize these flame-retardant features on the materials used to make the enclosures can help you choose the ideal enclosure for your project.

Understanding Flame Ratings

5VA (Surface Burn)

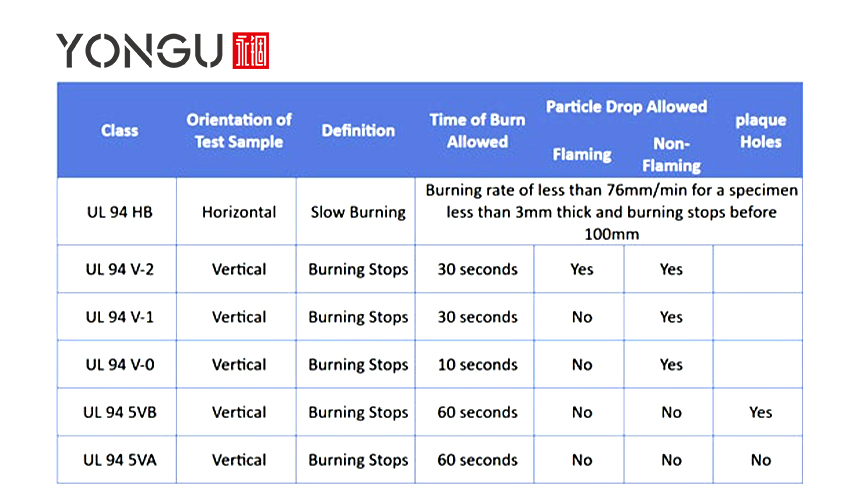

Flaming ends after five applications to a test bar for five seconds each of a flame hotter than that required in altitude burn testing in less than 60 seconds. On test samples, there would not be a burn-through or a hole. The highest and most flame-resistant classification is UL94.5VB (Surface Burn)

After five exposures of heating more prominent than that used in Altitude heat testing for five seconds each to a test bar, burning finishes within 60 seconds. There will be a burn-through hole in the test specimens.V-0 (Vertical Burn)

After 2 applications of a flame to a tester bar for ten seconds each, the burning stops within ten seconds.V-1 (Vertical Burn)

After 2 applications of a flame to a tester bar for ten seconds each, the burning stops after sixty seconds. Burning drops are not permitted.V-2 (Vertical Burn)

After 2 applications and a test bar to a flame for ten seconds each, the burning stops after 60 seconds. Dripping flames Were permitted.H-B (Horizontal Burn)

Burning occurs slowly horizontally on a 3millimeters large form at a value of less than 3 min and stops before going to the 5 points. Materials with an H-B rating are regarded as self-extinguishing. This is the UL94 rating that is the least flame-retardant.Polycase provides enclosures that adhere to the strictest industry standards for chemical and solvent resistance, water and dust resistance, and flame-retardant materials. Verify the material requirements for each model to be confident you are selecting the right thing. You may get material specification papers immediately on the product pages.

UL 94 Flaim Ratings

When heated to a tiny open flame under supervised laboratory circumstances, conductive polymers used in gadgets and appliances are measured and described by UL 94 for their flammability qualities. The test does not aim to depict the dangers of material in actual fire conditions; instead, it describes and quantifies the melting point of plastic materials in reaction to heat and flame. The ease of combustion, burning rate, flame spread, and intensity of burning materials are all documented by UL's testing procedure.It's crucial to remember that this standard does not cover polymeric materials used in construction project applications (ASTM E84 or UL723). As an illustration, polishing material is used in furniture, canopies, awnings, skylights, signs, and other decorative items.

Horizontal Testing

The UL 94 rating for HB testing is the lowest and least flame-retardant, and it is typically thought to be the most straightforward flammability test to pass. Normally, portable, attended, intermittent-duty domestic appliance enclosures should have a UL 94 HB rating (e.g., hair dryers).Testing vertically (V-0, V-1, V-2) (From most significant to least)

This test, which evaluates self-extinguished materials according to three classes UL 94 V-2, V-1, and V-0), usually is appropriate for portable, unmanaged, intermittent-duty electrical components, e.g., coffee makers.A specimen is held vertically, and the bottom of the experiment is exposed to flame. Until the material self-extinguishes, the flame is applied for ten seconds, withdrawn, and then reapplied for ten seconds. Five samples are evaluated in two sets.

K-Series Electronic Enclosures at Yongu

You should consider many factors of enclosure design, such as sizes, materials, rating systems, etc., when hunting for an electronics enclosure factory to create custom enclosures. It is essential to comprehend each material's characteristics, advantages, and disadvantages. Their designers and engineers usually choose the components for aluminum electronic enclosures based on the necessary parameters and the device's unique features.

Yongu K series produces flame-rated electronic enclosures in a very reliable quality. Metal housing with a stylish aluminum profile is ideal for audio amplifiers, network equipment, measurement devices, FA control boxes, etc. Several housing types are available, including flange, tilt, mobile, and hinge housing.

Aluminum flame-rated enclosures for electronic applications are available from Yongu Box and various other boxes.

Conclusion

We hope you understand the electronic enclosures and plastic enclosure testing and flamming.With its excellent range of electronic enclosures, Yogu Box leads the market for producing enclosures that protect at an affordable price. In addition, these electronic enclosures each have distinctive qualities that make them perhaps the best solution for your electronic enclosure requirements.

We also offer a live chat option for more optimized results, for that please visit our website and select the live chat button at the bottom right-hand corner of the page.

For further information and customized product of your requirements, please follow our FACEBOOK for more updates and informations.

You can also contact us at +86 13326782625 or write us [email protected].