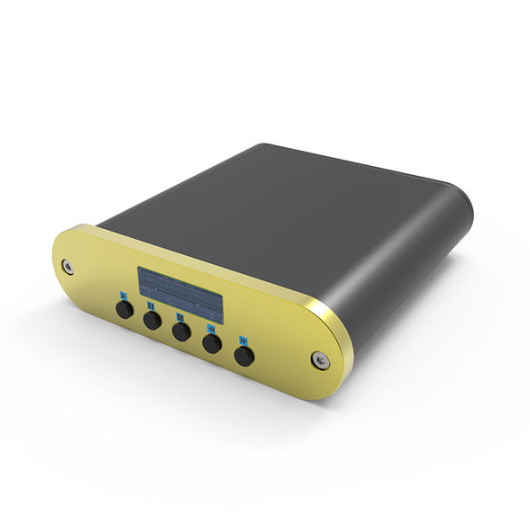

In the realm of protective casings and enclosures, split aluminum enclosures stand out as versatile and reliable options. These enclosures, crafted from aluminum and designed in a split format, offer a range of advantages across diverse applications. Let’s dive into the ins and outs of these enclosures to understand their functionality, advantages, applications, and customization potential.

What is A Split Aluminum Enclosure?

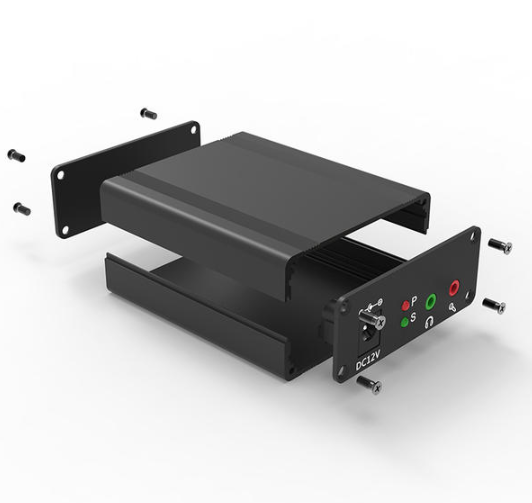

A split aluminum enclosure is a protective casing made from aluminum that is divided into two or more segments, allowing for easy access to the interior components. Typically, these enclosures are designed with precision to provide a secure fit while allowing for convenient assembly and maintenance of enclosed equipment or devices. The split design facilitates hassle-free installation, repairs, and modifications without compromising on the enclosure's protective capabilities.

What are the Advantages of Using Split Aluminum Enclosures?

Split aluminum enclosures offer a range of advantages that make them a preferred choice across industries:

Accessibility

The design of split aluminum enclosures allows easy access to internal components. The ability to open the enclosure quickly simplifies maintenance, repairs, and upgrades, reducing downtime significantly.

Durability

Crafted from aluminum, these enclosures boast exceptional durability. Aluminum is resistant to corrosion, rust, and degradation, ensuring the longevity of the enclosure even in harsh environments. This durability provides a safeguard for sensitive equipment housed within.

Environmental Resistance

Split aluminum enclosures excel in challenging conditions. They withstand moisture, extreme temperatures, dust, and other environmental factors, making them suitable for both indoor and outdoor applications.

EMI Shielding

Many split aluminum enclosures offer electromagnetic interference (EMI) shielding, crucial for protecting electronic components from external electromagnetic radiation. This shielding preserves the integrity and functionality of sensitive equipment.

Customization Options

Manufacturers often provide customization options, allowing alterations in dimensions, additional features like hinges or locks, and various surface treatments. This flexibility enables tailored solutions that meet specific technical or aesthetic requirements.

Cost-Effectiveness

Despite their durability and protective qualities, split aluminum enclosures often offer cost-effective solutions. Their long lifespan and minimal maintenance needs contribute to their cost efficiency over time.

Lightweight Design

Aluminum is inherently lightweight compared to other metals, making these enclosures easier to handle during installation and maintenance.

Sustainability

Aluminum is a recyclable material, contributing to sustainability efforts in manufacturing and reducing environmental impact.

What are the Applications of the Split Aluminum Enclosures?

Split aluminum enclosures find extensive application across diverse industries due to their versatile nature and robust properties. Some common areas of use include:

Electronics and Telecommunications

These enclosures are prevalent in housing sensitive electronic components, circuitry, and communication equipment. Their EMI shielding capabilities safeguard delicate electronics from interference, ensuring optimal functionality.

Industrial Automation and Control Systems

In industrial settings, split aluminum enclosures protect control systems, instrumentation, and machinery from environmental factors and mechanical damage. They are vital for maintaining uninterrupted operations in manufacturing facilities.

Aerospace and Defense

The durability of aluminum enclosures makes them suitable for aerospace and defense applications. They safeguard electronic systems, communication devices, and sensitive equipment in aircraft, vehicles, and military installations.

Renewable Energy Infrastructure

Split aluminum enclosures are utilized in solar energy systems, wind turbines, and other renewable energy installations. They withstand outdoor conditions and protect control panels, inverters, and monitoring systems in these environments.

Telecommunications Infrastructure

They are integral in housing network equipment, fiber optic connections, and communication hardware, especially in outdoor installations where weatherproofing and protection against environmental elements are crucial.

Medical Devices and Healthcare

In the medical field, these enclosures protect sophisticated medical equipment, diagnostic devices, and sensitive instruments from both physical damage and electromagnetic interference, ensuring reliable operation.

Transportation and Automotive Industry

They find application in vehicles, railroads, and transportation systems, where they protect electronic control units (ECUs), sensors, and other critical components from harsh conditions and vibrations.

Outdoor Surveillance and Security Systems

Split aluminum enclosures are used to protect surveillance cameras, sensors, and security equipment in outdoor environments, ensuring their functionality despite weather variations.

Conclusion

Finally, split aluminum enclosures serve as robust protective housings that cater to a wide array of industrial and commercial needs. The split aluminum enclosures can bring you a multitude of benefits, so they are the top choice for securing valuable equipment and ensuring operational efficiency across various sectors.