In the realm of electronics, a crucial yet often overlooked component is the circuit board enclosure. Serving as a protective casing for delicate circuitry, the enclosure plays a pivotal role in safeguarding electronic devices from environmental factors, mechanical damage, and electromagnetic interference. Let's delve into the intricacies of these enclosures, exploring their significance and the materials commonly employed in their construction.

What is A Circuit Board Enclosure?

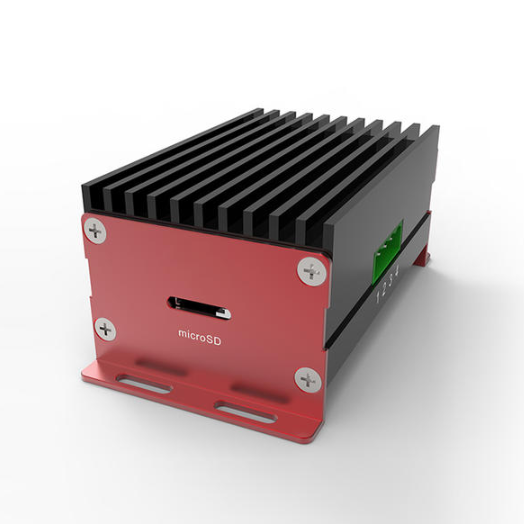

A circuit board enclosure is a protective housing or casing designed to enclose and safeguard electronic circuit boards and components. These enclosures come in various shapes, sizes, and materials (like plastic, metal, or a combination). They may feature openings for connectors, ports, or displays while providing adequate ventilation to prevent overheating of the enclosed electronics.

What Material is Commonly used for A Circuit Board Enclosure?

Circuit board enclosures can be made from various materials, each offering different properties and advantages:

Plastic

Plastic enclosures, such as ABS (Acrylonitrile Butadiene Styrene) or polycarbonate, are popular due to their affordability, lightweight nature, and ease of customization. They are also non-conductive, making them suitable for many electronic applications.

●ABS (Acrylonitrile Butadiene Styrene): This thermoplastic is widely used due to its affordability, lightweight nature, and ease of molding. It's non-conductive and can be easily customized through methods like injection molding to create various shapes and sizes.

●Polycarbonate: Known for its high impact resistance and transparency, polycarbonate is often chosen for applications where visibility of internal components is necessary along with protection from physical damage.

●ABS (Acrylonitrile Butadiene Styrene): This thermoplastic is widely used due to its affordability, lightweight nature, and ease of molding. It's non-conductive and can be easily customized through methods like injection molding to create various shapes and sizes.

●Polycarbonate: Known for its high impact resistance and transparency, polycarbonate is often chosen for applications where visibility of internal components is necessary along with protection from physical damage.

Metal

Aluminum and steel are common metals used for enclosures. Metal enclosures offer better shielding against electromagnetic interference (EMI) and provide enhanced durability and protection against physical damage. They are often used in industrial or high-stress environments requiring extra ruggedness.

●Aluminum: Aluminum enclosures offer excellent heat dissipation properties, making them suitable for electronic devices prone to heat buildup. They are also lightweight and can be easily machined or formed into different shapes.

●Steel: Steel enclosures are durable and provide robust protection. They're often used in harsh industrial environments where extra strength and protection against external forces or tampering are required.

●Aluminum: Aluminum enclosures offer excellent heat dissipation properties, making them suitable for electronic devices prone to heat buildup. They are also lightweight and can be easily machined or formed into different shapes.

●Steel: Steel enclosures are durable and provide robust protection. They're often used in harsh industrial environments where extra strength and protection against external forces or tampering are required.

Composite Materials

Some enclosures use composite materials, which combine properties from various materials. Fiberglass-reinforced enclosures, for example, offer a balance between durability and weight.

Die-Cast Enclosures

These enclosures are made using a die-casting process, often using materials like aluminum or zinc. These materials are melted and poured into a mold (die) under high pressure, resulting in strong, precisely shaped enclosures. They're known for their excellent EMI shielding capabilities and robustness. Die-cast enclosures provide good heat dissipation properties and are often used when heat management is critical for enclosed electronics.

What are the Advantages of the Circuit Board Enclosure?

Circuit board enclosures offer several advantages that are crucial for electronic devices:

Protection from Physical Damage

Enclosures safeguard delicate circuit boards and components from external elements like dust, moisture, accidental spills, and physical impacts, prolonging the lifespan of the electronics.

Safety

They provide a barrier between the internal electronics and external users, preventing accidental contact and reducing the risk of electrical shock or injury.

EMI Shielding

Certain enclosures, especially those made of conductive materials like metal, help mitigate electromagnetic interference. This shielding preserves the integrity of the circuitry and prevents interference with nearby devices.

Environmental Protection

Enclosures designed for outdoor or harsh environments offer resistance against extreme temperatures, humidity, and exposure to chemicals, ensuring the electronics function reliably under diverse conditions.

Customization and Flexibility

Enclosures can be tailored to specific device requirements in terms of size, shape, mounting options, and additional features like cutouts for connectors, displays, and buttons.

Heat Dissipation

Enclosures made from materials with good thermal conductivity, like aluminum, aid in heat dissipation, preventing overheating and maintaining optimal operating temperatures for the enclosed electronics.

Aesthetic Appeal

Enclosures contribute to the visual appeal of the device and its overall design. They can be designed to match branding guidelines or aesthetics desired by the product designers.

Compliance and Certifications

Enclosures can be engineered to meet industry-specific regulations and certifications, such as IP (Ingress Protection) ratings for water and dust resistance or standards for safety in hazardous environments.

Ease of Assembly

Well-designed enclosures often facilitate ease of assembly and maintenance, allowing for efficient production processes and servicing of the electronics.

These enclosures come in various shapes, sizes, and materials (like plastic, metal, or a combination). They may feature openings for connectors, ports, or displays while providing adequate ventilation to prevent overheating of the enclosed electronics.

These enclosures come in various shapes, sizes, and materials (like plastic, metal, or a combination). They may feature openings for connectors, ports, or displays while providing adequate ventilation to prevent overheating of the enclosed electronics.

Conclusion

All in all, a circuit board enclosure serves as a crucial guardian for electronic components, shielding them from environmental hazards and ensuring their optimal performance.

When selecting the material for these enclosures, factors such as environmental conditions, shielding requirements, and manufacturing constraints should guide the decision-making process.

With a diverse array of materials available, each offering unique properties, choosing the right enclosure material is pivotal in guaranteeing the functionality and longevity of electronic devices.

When selecting the material for these enclosures, factors such as environmental conditions, shielding requirements, and manufacturing constraints should guide the decision-making process.

With a diverse array of materials available, each offering unique properties, choosing the right enclosure material is pivotal in guaranteeing the functionality and longevity of electronic devices.