Dust collection will begin to impact your system's performance after two years. However, no one can make an accurate and precise prognosis of the life span decrease of electronics.

HOW DOES DUST AFFECT ELECTRONIC PRODUCTS?

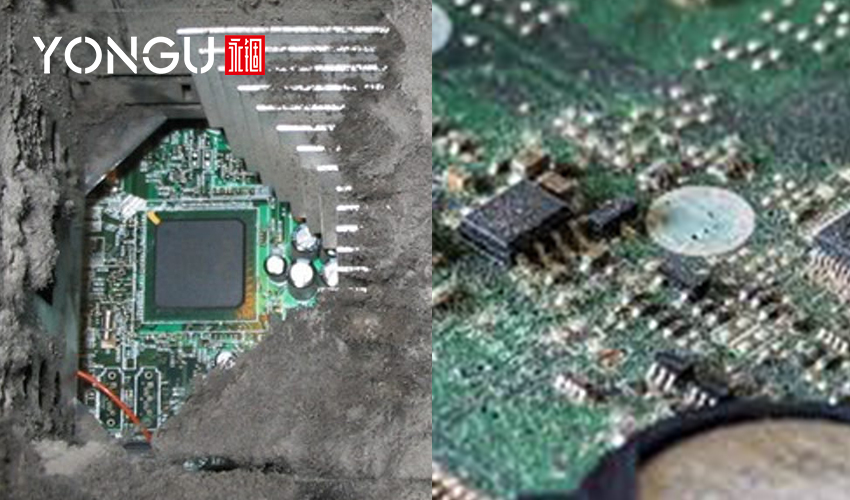

The accumulation of dust on the interior of a device is one of the primary contributors to untimely failure and problems with dependability.

When exposed to dust, many ICs malfunction or fail; currently available integrated circuits (ICs) can have as many as one hundred electrical connections exposed per square millimeter. The most vulnerable integrated circuits (ICs) are those with a metal top that may be used as heat sinks. This area of metal has to be somewhat clean. As soon as dust and air come into contact, it acts like an insulating blanket and prevents the essential standard cooling from taking place. Dust over the connections of the integrated circuits can function as an insulator, leading to overheating and potential electrical shorts. With enough dust in the air, the temperature can rise by as much as 20 degrees Fahrenheit. It is a significant rise that might spell disaster.

Dust may easily find a hiding place in your electronics' crevices, such as the ports, sockets, and other spaces between components. The formation of a dust barrier in certain areas might cause one of the following issues:

- A lack of ventilation can cause internal temperatures to rise too high, leading to overheating

- Humidity

- Conductivity

- Relays, switches, and connections with subpar contact quality

- Arcing and carbon tracking is possible in high-voltage devices

- Harder to fix or restore to the previous condition

APPLICATIONS OF DUSTPROOF ENCLOSURES

- Circulating Dust

- Falling Dirt

- Low maintenance

- Cost savings in terms of protection for expensive electronics modules and components

IP & NEMA RATED PROTECTION FOR DUSTPROOF ENCLOSURES

The equipment is typically housed inside of an enclosure to prevent people or animals from coming into contact with live or moving parts of certain equipment. It serves two purposes: first, it protects the live parts of the equipment from being contacted by foreign solid bodies or liquid, and second, it prevents people from coming into contact with the life or moving parts.

The Ingress Protection (IP) rating or the NEMA rating is a measurement that may determine how much protection such an enclosure provides. While both the NEMA 250 and the IEC standard 60529 rating systems establish levels of protection against contaminants like water and dust, they do so using distinct test techniques and characteristics.

The first number indicates resistance to solid objects; ratings range from 0 indicating no protection to 6 indicating no entry of dust; the second indicates resistance to liquids; ratings range from 0 indicating no protection to 9 indicating high-pressure hot water from a variety of angles.

The NEMA ratings for non-hazardous places range from Type 1 up to Type 6, and then from 11 up to Type 13, whereas the NEMA ratings for hazardous locations range from Type 7 up to Type 10.

An IP rating of 6 or above (Dust Tight, No Ingress of Dust) is what you want to see if your application necessitates a dust-tight enclosure; therefore, look for the options among IP65 to IP68. A grade of 6 denotes an entirely dust-proof enclosure.

IP ratings beginning with 5 (Dust Protected, Prevents intrusion of dust sufficient to cause injury) are ideal for applications that require dust resistance but don't necessitate total dust tightness; nevertheless, IP55 and IP56 enclosures are also good options.

There is no one-to-one correspondence between IP and NEMA ratings; however, we may say that IP54 is equal to NEMA 3S, IP66 to NEMA 4 or 4X (with the 4X offering further protection against corrosion), IP67 to NEMA 6 and 6P, and IP52 to NEMA 12 and 12K in terms of the degree of protection they offer.

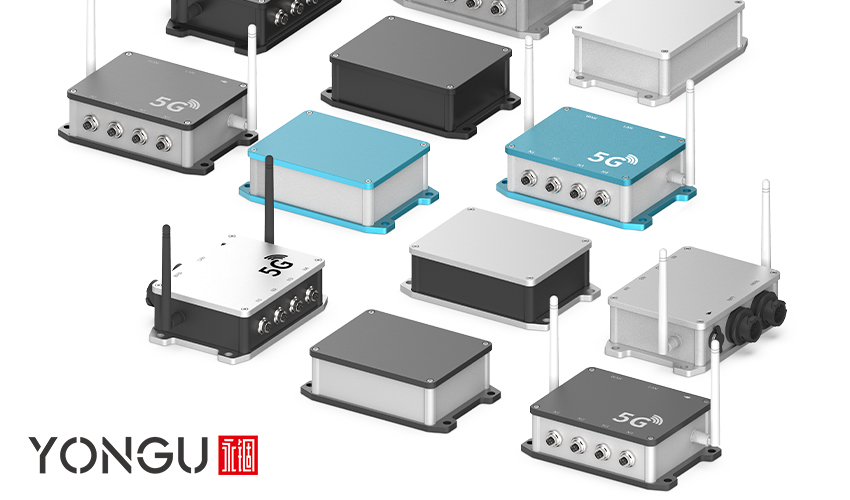

YONGU DUSTPROOF ENCLOSURES

Finding the optimal mix between performance, functionality, aesthetics, and affordability when you require a dust-proof enclosure can be difficult. Offering dust-proof enclosure designs and materials at affordable costs, YONGU makes it simple to discover the combination that works for you.

Regardless of how extreme your application is, we have a dust-tight enclosure type and enclosure accessory that will work well.

- YONGU M02 80*80*L IP67/IP68 Aluminum Box

- YONGU K11C 66*30*L Aluminum Extrusion Box

- YONGU L03A 120*75*H Outdoor Waterproof Enclosures

- YONGU B01 248*2U Electronic Enclosures

- YONGU L02C 110*65*H IP67 Aluminum Box

- IP67/68 Aluminum Enclosures.

- Able to withstand rigorous, continuous use.

- The dispensing ring is effective at keeping the seal against moisture and dust.

- Shockproof die-cast construction.

- Make use of conductivity between the rough interior surfaces.

- High capability for carrying weight.

- Customized sizing, shaping, and coloring

You can also contact us at +86 13326782625 or write us [email protected].