It is advantageous to employ wireless transmissions if cables are cumbersome or impossible to use. Field-based control and monitoring systems require robust enclosures to ensure the data's integrity. It is vital that the amount of energy received be high enough for the signal to be differentiated from the background noise in wireless data transmissions such as radios.

Radio receivers retrieve all signals on the frequency at which the receiver is set. Wi-Fi operates at a frequency of 2.4 GHz, and for advanced noise reduction, some devices operate at 5 GHz. There must be at least 20 dBm more Wi-Fi signal strength than the noise or spurious transmissions to transmit data. The signal level drops below the 20 dBm threshold when shielding a signal, reducing its SNR. As a result, there are data transfer errors. There would be sluggish browsing or no browsing at all on a laptop.

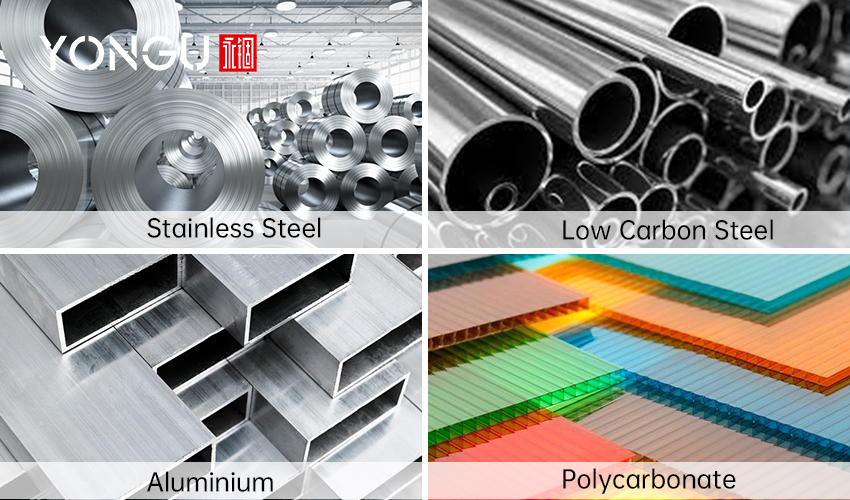

Types of Materials Under Consideration

Stainless Steel

- Pros

Impact Resistance

Natural Shielding from EMI/RFI

- Cons

Low Carbon Steel

- Pros

Natural Shielding from EMI/RFI

- Cons

If the coating wears off, susceptible to rust

Aluminium

- Pros

Lighter than steel

- Cons

Polycarbonate

- Pros

Allows RMI/EMF Transmission

- Cons

PVC

- Pros

Allows RMI/EMF Transmission

- Cons

Limited Temperature Range

Polymer Fiber Glass Composites

- Pros

Weight to Strength Ratio

Allows RMI/EMF Transmission through Materials

- Cons

Selection of Enclosure Material For Wireless Control

Materials that designers can choose should be thoroughly researched to ensure that they are suitable for the intended use. There are specific requirements for each application. Many of the capabilities are, in fact, inherent in particular materials.

However, an incorrect or overestimated choice of material might have several consequences throughout a product's lifespan. It's good to go for a product that covers all of your needs.

Metallic Enclosures

Stainless steel and other premium metals can be utilized in applications where corrosion resistance, high thermal stability, and extended life are crucial. Direct-wired manufacturing and process control systems may necessitate RFI/EMI shielding to protect the designs from the electrical noise common in those applications. The components inside a metal enclosure are automatically shielded from such external disturbance, enhancing the system's overall robustness. Other heavy machinery, such as that used in the machine tool sector, can also benefit from this shielding. Chemical resilience is frequently required in these kinds of applications. Additional shielding may be necessary for non-metal enclosures in some cases to protect sensitive electronics.The problem is that many OEMs are hesitant to pass on the higher cost and excessive weight of their products. The environment in which enclosures are to be put is an important consideration. They deform readily; however, they're hard to drill or penetrate. Steels have great strength but poor toughness.

The most crucial consideration in the design of a wireless application is the choice of the enclosure, and designers need to be aware that metal enclosures might impede radio frequency signals. Customers occasionally install internal cable assemblies to alleviate this problem by connecting the wireless module to a bulkhead connection. An external antenna may be screwed directly onto the bulkhead connector using the adapter. A metallic enclosure with an external antenna often performs better than one with a built-in one.

Composite Enclosures

Electronic impulses may travel easily through composite materials. Consider that exterior antennas are susceptible to corrosion, ferrous oxide degradation, and natural ambient interference from the surrounding environment, among other environmental factors. Non-metal enclosures in communications applications have become more popular due to this exact reason: they allow for the free passage of electronic signals. Choosing an enclosure material that can withstand corrosion withstand harsh chemicals, and retain a durable exterior is more important since most non-metal enclosures allow electronic signals to pass through the enclosure. Additional adjustments can simply be made to non-metal enclosures. Additional cutouts are available, whether for short security checks, downloading information, or audio/video hookups. Over the years, non-metal enclosures have shown to be long-lasting and have safe and lockable lids to prevent illegal entry. They're more durable and don't require an extra antenna for wireless systems to work.Metal enclosures have one drawback: they impair the gasket seal, which is critical to preventing internal controls from being damaged by moisture, dust, and other external causes. In non-metal enclosures, the seal is frequently housed in a groove in the lid to prevent being damaged by being dropped on its face.

Since no external antenna is required to transmit electronic signals, non-metallic materials have a significant advantage over metallic ones. You can quickly drill holes for audio/video hookups, and it's non-conductive and can resist temperatures as low as -40 degrees Fahrenheit or higher.

However, even though non-metallic enclosure materials may withstand some oxidation, metal enclosures, especially aluminium alloys coupled with other alloys, are often the best solution in many circumstances, and YONGU provides this service. The operating system, design layout, component location, and other factors will influence performance. Any one of a plethora of circumstances might cause a gadget to malfunction.

New design issues emerge as more Internet of Things devices are released into the market. Heavy-duty metal enclosures are one primary source of confusion for engineers. Devices require metallic casings for long-term durability and protection. Antenna performance is adversely affected by metal components. When exposed to electromagnetic fields, conductive surfaces become charged and emit radiation. As a result, there are several problems with the antenna's effectiveness.

Ways to Increase Wireless Antenna Performance in Metal Enclosures

- Slit and Gap between enclosure and material

Engineers frequently underestimate the impact of window size on performance and ignore other essential considerations. For example, the antenna and enclosure must be separated by a larger-than-normal gap. Even if performance is adequate, it may not be enough.

This also affects the device's overall performance and quality. Metal enclosures are preferred because of their resistance to corrosion, abrasion, and endurance. Devices that have proper gap adjustments will be less vulnerable to these impacts.

- Hybrid Enclosures

A disadvantage of hybrid enclosures is the high cost and in-depth knowledge. Complexity increases in manufacturing processes as a result of accumulated development required. This restricts their application to initiatives that have large budgets and well-supported marketing strategies.

These antenna lines are likely to be covered by hands and skin. User testing is essential to guarantee that they aren't covered while in use.

- External Antenna

- Multilayer Antenna Opt

This is a more cost-effective alternative to the hybridization of an enclosure and gives higher performance. Because of their modest size, they are also much easier to conceal than external antennas.

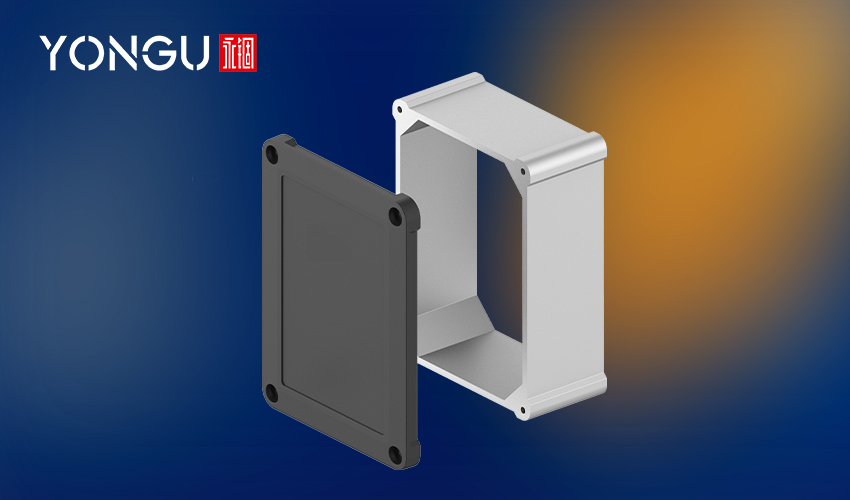

YONGU Sheet Metal Box

YONGU can help with a wide variety to cater to all the above problems for wireless enclosures by combining the advantages of metal and non-metal enclosures. YONGUBOX offers completely customizable from every dimension in two different series, including E Series & S Series.

YONGU L Series

Durable enclosures rugged enough for indoor or outdoor applications

L Series include around 24 different models, including

- Outdoor Electrical & Water Proof Boxes

- Waterproof Plastic Enclosures

- Waterproof Electrical Enclosures

- IP67 Aluminum Boxes

- Waterproof Electrical Junction & Power Boxes

- Weatherproof Electrical Enclosures

- Waterproof Metal Junction Boxes

- Waterproof Box for Boat

- Waterproof Battery Boxes

- Automotive Waterproof Electrical Junction Boxes

- Waterproof Connection Boxes

- Waterproof PCB Boxes

- Waterproof Switch Boxes

- Waterproof Underground Electrical Junction Boxes

- Rugged and robust for heavy-duty use.

- Maintaining waterproof and dustproof functioning is more accessible by using a distribution ring.

- Diecast aluminium housing that is resilient to shocks

- The unfinished interior surfaces can be used to achieve conductivity

- Plastic Covers, Stainless Steel Sockets, Alu pads, and case with dispensing rings

YONGU M Series

Highly versatile enclosures at an economical price

M Series include around 11 different models, including

- IP67/IP68 Aluminum & Waterproof Boxes

- weatherproof electrical boxes

- outdoor electrical junction boxes

- waterproof junction boxes

- outdoor electronic boxes

They have the following advantages in general.

- Rugged and robust for heavy-duty use.

- Maintaining waterproof and dustproof functioning is more accessible by using a distribution ring.

- Diecast housing that is resilient to shocks with carbon steel nickel counter head screws

- The unfinished interior surfaces can be used to achieve conductivity.

For further information and customized product of your requirements, please follow our FACEBOOK for more updates and informations: https://www.facebook.com/Foshan-Gof-Electronic-Machine-Co-Ltd-104706631749290

You can also contact us at +86 13326782625 or write us [email protected].