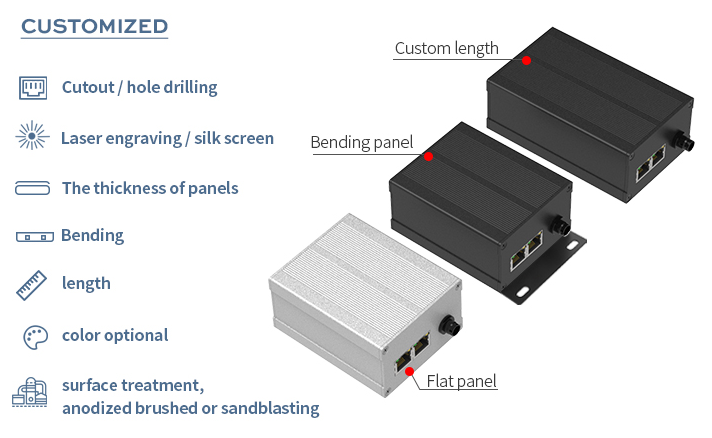

When you are planning to make the customization enclosure from some instrument enclosure manufacturers, you may often hear some technical terms of the enclosure box about the treatment. These terms may be out of your knowledge because they involve complicated fabrication techniques. Luckily, this post covers the commonly used terms about finish treatment techniques, helps you further understand customized enclosure.

Enclosure Polishing

Enclosure polishing is one of the common finish treatments in enclosure fabrication. This technique is used to make aluminum enclosure that has a smooth and bright surface and eliminates the burrs. Current, six enclosure polished techniques are available in the enclosure processing----mechanical polishing, electrolytic polishing, chemical polishing, ultrasonic polishing, hydro finish, and magnetic polishing. These techniques feature various benefits.

Enclosure Brushed

The brushed treatment is the second common finish treatments in the customization aluminum box. The brush treatment could improve the durability and scratch resistance of the panel of the electronic components enclosure.

The above picture shows you the effect of the anodized aluminum enclosure with the brush treatment. It is constructed with two body-with easily removable belly plates which give access to the top interior of the enclosure. Different from the ordinary custom aluminum box, it presents you with a low-key surface that seems like the matte style. In addition to the special surface, it also presents a great performance in the shielding. The EML shielded in this enclosure could keep the internal electronic components away from interference.

Enclosure Sandblasting

Sandblasting is a processing method through which it is possible to obtain excellent cleaning and surface preparation for secondary finishing operations. During the sandblasting process, the high-velocity steel abrasive is used for flattening a rough surface, roughening a smooth surface, shaping a surface, or removing surface contaminants.

The above product is the typical example of an enclosure with sandblasting. The sandblasting makes the panel of the electric enclosure delicate but simple. The above product is the typical example of an enclosure with sandblasting. The sandblasting makes the panel of the electric enclosure delicate but simple. The sandblasting makes this pcb board aluminum box's panel evener and smoother, which could provide a clean surface for the secondary finishing operations.

Enclosure Silkscreen

The silkscreen is the easiest and least expensive way in the enclosure customized service. the panel of the enclosure can be silkscreened anything that you need from labeling operators or externally installed devices to your company name and logo. If you want to add a serial number on your customization aluminum box, you also could adopt the silkscreen to add it. But, there is one thing you need to notice. The silk-screening marks are not permanent. It is susceptible to being worn off or scratched off from hand tools on smooth metal surfaces like stainless steel or aluminum.

Final Words

All in all, when comes to the customized enclosure, the finish treatment is one of the most important factors affecting the whole body of the enclosure. I hope this post could solve your confusion about the finished surface treatment and help you design the perfect electrical box.