Instrument enclosures play a crucial role in safeguarding delicate equipment, ensuring their functionality, and protecting them from environmental hazards. Whether you’re dealing with sensitive electronics, scientific instruments, or industrial control devices, selecting the right enclosure is pivotal. With a myriad of options available, here’s a comprehensive guide to help you navigate through the selection process.

Understand Your Equipment's Needs

Before diving into enclosure options, comprehensively understand your equipment's requirements. Consider factors like size, heat dissipation, moisture sensitivity, and protection against dust or electromagnetic interference. Knowing these specifics will streamline your search for the ideal enclosure.

Material Matters

Enclosures come in various materials such as plastic, metal, and fiberglass, each with its pros and cons. Metal enclosures like aluminum or stainless steel offer robust protection and excellent electromagnetic shielding but might be heavier and more expensive.

On the other hand, plastic enclosures are lightweight, cost-effective, and often suitable for indoor use. Fiberglass enclosures strike a balance between the two, offering good protection and moderate cost.

On the other hand, plastic enclosures are lightweight, cost-effective, and often suitable for indoor use. Fiberglass enclosures strike a balance between the two, offering good protection and moderate cost.

Environmental Considerations

Evaluate the environment where the instrument will be used. Outdoor settings may require enclosures with higher IP (Ingress Protection) ratings to safeguard against moisture, dust, or extreme temperatures. For indoor applications, factors like aesthetics and integration with existing equipment may be more important.

Certain environments demand specialized enclosures. For extreme temperatures, thermal management features like heaters or insulation might be necessary to maintain ideal operating conditions. In corrosive atmospheres, stainless steel enclosures offer exceptional resistance. For hazardous locations, enclosures meeting explosion-proof standards ensure safety.

Certain environments demand specialized enclosures. For extreme temperatures, thermal management features like heaters or insulation might be necessary to maintain ideal operating conditions. In corrosive atmospheres, stainless steel enclosures offer exceptional resistance. For hazardous locations, enclosures meeting explosion-proof standards ensure safety.

Size and Customization

Ensure the enclosure accommodates not just the instrument's current size but also any potential future expansions or modifications. Some projects might benefit from custom-designed enclosures to perfectly fit the instrument’s specifications, offering added protection and functionality.

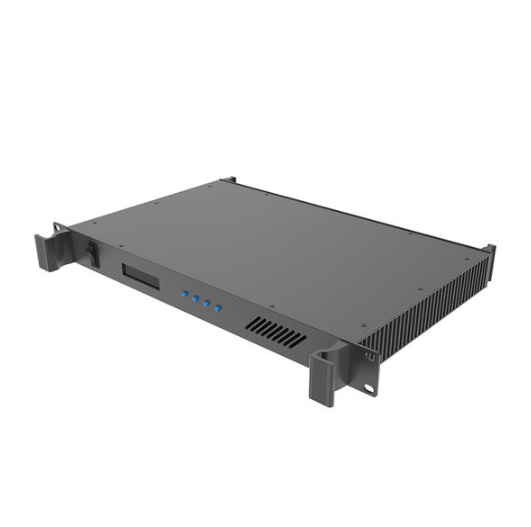

Mounting Options

Consider how you plan to mount the enclosure. Wall-mounted, pole-mounted, or rack-mounted enclosures offer different advantages depending on the intended use and available space. Compatibility with mounting hardware and ease of installation are crucial factors to consider.

Ventilation and Cooling

For instruments generating heat, proper ventilation or cooling mechanisms within the enclosure are vital. Louvers, vents, or fans can help dissipate heat, preventing overheating and ensuring optimal performance.

Compliance and Certifications

Certain industries or applications may require compliance with specific standards or certifications (UL, NEMA, IP, etc.). Ensure the chosen enclosure meets these requirements to avoid complications or safety issues down the line.

Budget Considerations

Set a realistic budget and balance it with your requirements. While cost is a significant factor, compromising on quality or essential features might lead to long-term expenses or equipment vulnerabilities.

Seek Expert Advice

When in doubt, consult with enclosure manufacturers, engineers, or experts in the field. Their expertise can provide invaluable insights and help you make an informed decision aligned with your needs.

Conclusion

Selecting the right instrument enclosure is a critical step in ensuring the longevity, functionality, and safety of your valuable equipment. By considering factors like material, environmental conditions, size, mounting options, and compliance requirements, you can make an informed choice that best suits your instrument's needs.