Today's market is highly competitive; therefore, products need a custom-designed enclosure that looks good and is easy to handle. A well-designed enclosure is a feat of art and science, as the designer must ensure that it serves its intended purpose while also striking an emotional chord with its intended audience.

Constructing an electrical and electronics enclosure that reflects the user's needs in every way would be difficult. Simple but effective operator controls, user-friendly features, low maintenance needs, low cost, and a sleek design are all hallmarks of a suitable panel enclosure.

As a result, there are a few factors that engineers should think about before creating the ideal enclosure. It is the most efficient method, both financially and in terms of time saved, for creating a flawless panel enclosure.

The electronics enclosure size and IP protection level are not the only factors to consider when designing a control panel. Instead, the focus should be on developing a straightforward yet functional layout.

ELECTRONICS ENCLOSURES DESIGN GUIDELINES & RECOMMENDATIONS

The long-term viability of your electronics project relies on the quality of the box build design used. Any industrial electronic enclosure needs to be designed with careful thought and evaluation in an account. The essence of your plan may be summed up in five words:

- Accommodate

- Material

- Transmission

- Layout

- Integration

Optimal Accommodation

Create a cost-effective, secure, and aesthetically pleasing electronics enclosure using 3D modeling. The realistic prices of machining, materials, and assembly of your product will also be impacted by the quantity you anticipate ordering.

The final product's dimensions are crucial. Shipping costs, and by extension, final retail prices, are affected by a product's dimensions and weight.

Constructing a suitable casing for a larger device may be more challenging.

Make that the device's design-for-manufacturability dimensions are met by consulting with a design or product development staff. Modeling in PCB layout can consider optimal space concerns and interfering concerns.

Determine Which Electronic Enclosure Material Is Right For You

When selecting the best material for your electronics enclosure, keep in mind the following:

- Reliability

- Ductility

- Availability

- Cost

The use of metal in product construction is every day when strength and economy are paramount; however, it is essential to consult with your ECM to ensure that the form you've settled on can be efficiently mass-produced.

Plastic is more malleable and resistant to corrosion, so your manufacturer may readily make unusual shapes using customized molds. Avoid expensive tooling expenditures by using standard plastic electrical and electronics enclosures for low-volume production runs.

Always think about how the ultimate user will use the material. In many situations, you'll want to keep things contained:

- Outdoors

- In the ground or the water

- Dangerously high temperatures

- Elevated concentrations of moisture

Pour-in aluminum casing, for example, has a higher up-front cost than other materials. There should be no surprises when it comes to pricing when you work with an electronics manufacturing services company. A higher initial investment may be justified by the value of a more durable or uniquely branded product.

Verify Sufficient Transmission

Metallic enclosures should be avoided to improve wireless signal propagation.

However, there are exceptions to this rule, and some wireless devices require a metal casing for reasons like corrosion resistance.

To ensure optimal transmission and device safety, use an ECM that offers design advice.

Opt for a Carefully Conceived Layout and Design

Although the product's visual appeal isn't the most crucial factor, it could have a more significant impact than you think. Before making decisions affecting the product's aesthetics and functionality, it is essential to research the aesthetic practices of competitors in the sector. Think about if a branded look is something you want and if it's feasible given the expected number of orders.

Customers can choose from a wide range of gadget sizes, from small and discreet to prominent and noticeable. Find out who you're selling to and what they're looking for in terms of items.

BOM versus CAD

Before beginning production, verifying package compatibility by comparing the bill of materials (BOM) to the CAD is essential.

Consider the bill of materials the blueprint sent to your electronics manufacturing provider. Verify the complete BOM to prevent misunderstandings. Although it is possible to do this manually, it is more reliable to use dedicated tools to compare the BOM and CAD.

If you haven't yet found the perfect app for your needs, your ECM may be able to recommend one.

YONGU - TRUSTED ENCLOSURE MANUFACTURER

The role of your electronics enclosure contract manufacturer should extend beyond that of a simple PCB house into that of a full-fledged box-build assembly outsourcing partner. Selecting an electronics manufacturing services design partner with previous PCB and enclosure experience can increase your chances of success.

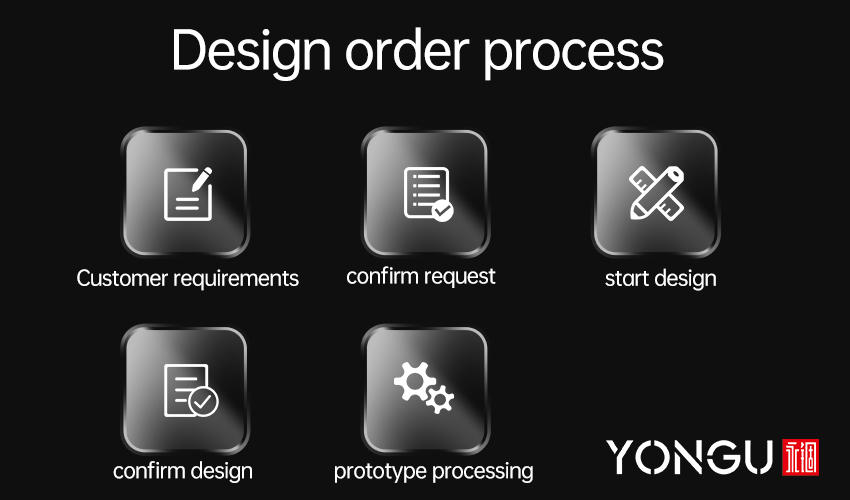

When it comes to the design of enclosures, YONGU offers the following.

Unique Prototype

Creating a custom look and feel for your prototype is one of YONGU's offerings. We accept orders for both original equipment and original design manufacturer goods. If you'd like your items to stand out from the crowd, we can assist you in creating a prototype with a new structure and look.

Machining Services

In addition to offering the finest machining, we also provide specialized services, including precise hole drilling and tight tolerance machining. Please provide your aluminum case.

Service for Anodizing Metals

Since our company operates its anodizing plant, we can meet your specific needs and specifications concerning surface treatment. Here, have the shiny aluminum case brought to you.

Dye sublimation Services

We provide laser engraving and silk screening services for colorized logos and text. We work hard to get the cool electronics enclosure box to you.

Qualified Inspecting Services

Our Quality Control team will inspect your metal packaging. Always have full command of your case with double orders during processing time.

Excellent Problem-Solving Through Engineering

The most outstanding solutions are engineered as part of YONGU's service. With 3D CAD and hand-drawn sketches, we can turn your ideas into a working prototype or a whole line of manufactured goods. We also supply potentially feasible solutions for a printed circuit board and other internal structural parts.

Handling the High-Quality Goods

YONGU's high-quality box processing service is just one of several. Instead of striving for frictionless technology, focus on enabling precisely accurate supply networks. Giving customers an aluminum case that is precise and sturdy is YONGU’s goal.

For further information and customized product of your requirements, please follow our FACEBOOK for more updates and informations.

You can also contact us at +86 13326782625 or write us [email protected].