In the realm of electronics, the significance of managing heat within devices cannot be overstated. One integral solution to this challenge is the implementation of heat sink enclosures. Let's delve into what these enclosures are, their advantages, drawbacks, and the necessary requisites for their optimal functioning.

What is a Heat Sink Enclosure?

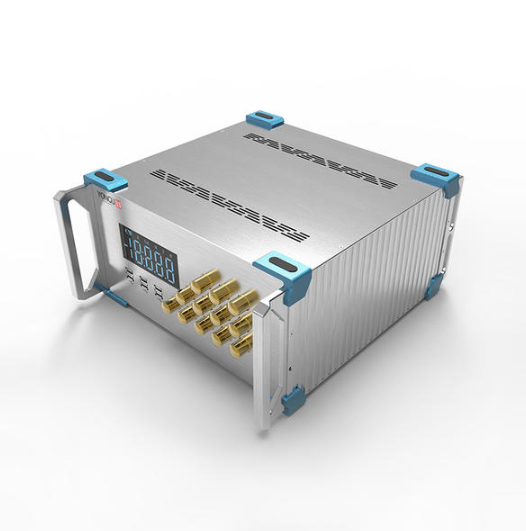

A heat sink enclosure is a specialized casing or framework designed to manage and dissipate heat generated within electronic devices. It incorporates a heat sink—a passive cooling device—that absorbs and transfers heat away from the device's critical components, ensuring optimal temperature regulation. These enclosures are engineered to create an efficient thermal pathway for heat to escape, thereby preventing overheating and potential damage to sensitive electronic parts.

The primary function of a heat sink enclosure is to facilitate heat dissipation and maintain the device's operational temperature within safe limits. It typically consists of heat-conductive materials like aluminum or copper and employs various design features to maximize the surface area for heat transfer and enhance airflow within the enclosure.

The primary function of a heat sink enclosure is to facilitate heat dissipation and maintain the device's operational temperature within safe limits. It typically consists of heat-conductive materials like aluminum or copper and employs various design features to maximize the surface area for heat transfer and enhance airflow within the enclosure.

What Are the Advantages of A Heat Sink Enclosure?

A heat sink enclosure combines the benefits of both a heat sink and an enclosure, offering several advantages:

Enhanced Heat Dissipation

The primary advantage of a Heat Sink Enclosure is its ability to efficiently dissipate heat generated within electronic devices. By incorporating a heat sink within an enclosure, it creates a dedicated space optimized for heat transfer, maximizing the dissipation of thermal energy.

Improved Thermal Management

The enclosure provides a structured framework that directs airflow and heat distribution, enhancing the heat sink's effectiveness. This controlled environment aids in maintaining consistent temperatures, preventing hotspots, and ensuring efficient thermal management across the device.

Protection and Shielding

Besides heat dissipation, the enclosure provides physical protection to the electronic components. It shields sensitive parts from external elements such as dust, moisture, or accidental impacts, safeguarding the device's integrity and longevity.

Space Optimization

Heat sink enclosures are designed to efficiently use available space, integrating heat dissipation features without significantly increasing the device's footprint. This optimization is crucial, especially in compact electronic designs where space is limited.

Versatility in Design

These enclosures offer flexibility in design, allowing engineers to tailor the structure and layout to suit specific devices or applications. This versatility ensures that heat dissipation is optimized according to the device's requirements.

Compatibility with Various Devices

Heat Sink Enclosures can be adapted to accommodate a wide range of electronic devices, from small-scale consumer electronics to larger industrial equipment. Their adaptability makes them a versatile solution for diverse technological applications.

Integration with Aesthetic Designs

In consumer electronics, where aesthetics are important, Heat Sink Enclosures can be designed to complement the overall appearance of the device. They can be incorporated seamlessly into the device's design without compromising functionality.

Maintenance and Durability

Heat Sink Enclosures often require minimal maintenance once installed. Their robust construction and efficient heat dissipation mechanisms contribute to the durability and reliability of the enclosed electronic systems.

What are the Disadvantages of a Heat Sink Enclosure?

While heat sink enclosures offer significant benefits in managing heat within electronic devices, they do come with certain limitations:

Increased Size and Weight

Integrating a heat sink and enclosure can add bulk and weight to the device. In applications where space and weight are critical factors, the additional size of the enclosure might pose challenges in design and portability.

Cost Considerations

Implementing heat sink enclosures often involves specialized materials and design considerations, which can increase production costs. This cost factor might be a limitation, especially for budget-sensitive projects or consumer electronics aiming for cost competitiveness.

Limited Cooling Capacity

In scenarios where extremely high heat dissipation is required, such as in high-powered systems or devices generating excessive heat, the passive cooling capacity of a heat sink enclosure might reach its limit. In such cases, additional cooling methods might be necessary.

Potential Design Complexity

The design and integration of heat sink enclosures can sometimes add complexity to the manufacturing process. Ensuring proper alignment, thermal conductivity, and effective heat dissipation might require intricate design considerations, impacting production timelines and costs.

Dependency on Ambient Conditions

Passive heat dissipation in heat sink enclosures relies on ambient airflow. In environments with poor airflow or high ambient temperatures, the efficiency of heat dissipation might be compromised, affecting the overall effectiveness of the enclosure.

Thermal Resistance Variability

Variations in material quality or surface finish of the enclosure components can lead to inconsistencies in thermal resistance. This variability might impact the overall heat dissipation performance, requiring meticulous quality control during manufacturing.

Space Constraints

In compact devices or systems with limited internal space, integrating a heat sink enclosure might be challenging. The need to accommodate the enclosure without compromising the device's functionality or design aesthetics can be a constraint.

Conclusion

All in all, heat sink enclosures play an indispensable role in maintaining the operational integrity of electronic devices by effectively managing heat dissipation. While they offer notable advantages in temperature control and device longevity, considerations such as size, cost, and design intricacies warrant careful assessment during their implementation.