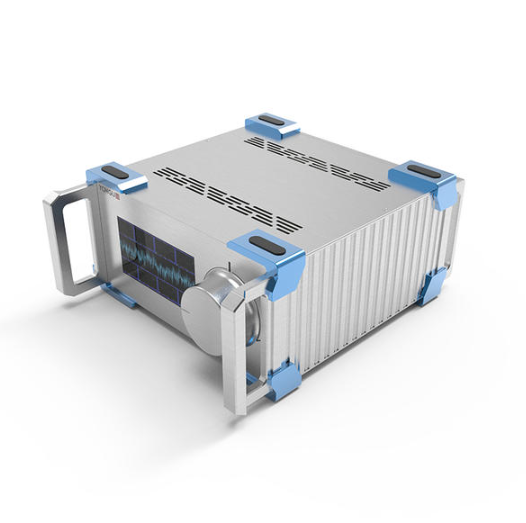

Anodized aluminum enclosures serve as essential protective housing for a wide array of projects, ensuring durability, aesthetics, and functionality. However, choosing the right enclosure demands a keen understanding of the material, project requirements, and customization options available in the market.

What is Anodization?

Anodization is a process that enhances the properties of aluminum, creating a protective oxide layer on its surface. This layer improves corrosion resistance, durability, and offers opportunities for customization through color and finish options.

Factors to Consider When Selecting an Anodized Aluminum Enclosure

In this section, the author would list some factors need to be considered when selecting an anodized aluminum enclosure.

Size and Dimensions

Begin by determining the dimensions required for your project. Anodized aluminum enclosures come in various sizes and shapes, so ensuring it accommodates your components comfortably is crucial. Consider potential growth or changes in your project's needs, as well.

Protection Levels

Evaluate the environmental conditions the enclosure will face. Will it be exposed to moisture, extreme temperatures, or corrosive elements? Enclosures with higher IP (Ingress Protection) ratings offer better resistance against dust, water, and other external factors. Anodized aluminum excels in providing protection against corrosion, but the enclosure design and sealing also play a significant role.

Assembly and Accessibility

Ease of access for maintenance, repairs, or modifications is crucial. Look for enclosures with accessible panels, appropriate openings for connectors, and provisions for mounting components securely.

Project Requirements

Before diving into enclosure selection, it's crucial to define project specifics such as size, shape, and environmental considerations. Whether it's indoor electronics or outdoor industrial use, understanding these parameters is fundamental.

Material Quality

The choice of aluminum alloy impacts the enclosure's performance. Consider the alloy type and the thickness of the anodized layer for optimal strength and protection.

Customization Options

Anodized aluminum enclosures often offer diverse customization opportunities. Evaluate the manufacturer's machining and finishing capabilities, color choices, and additional modifications like cutouts or branding options to align with project needs.

Heat Dissipation

For projects involving electronic components prone to generating heat, consider enclosures with features for effective heat dissipation. Some designs include heat sinks or fins to aid in thermal management.

Cost and Budget Considerations

Balancing quality with cost-effectiveness is pivotal. Assess the long-term value an enclosure offers concerning durability and functionality.

Application-Specific Considerations

For electronics, consider the enclosure's shielding capabilities, grounding requirements, and its thermal management properties to ensure optimal performance and protection for sensitive components.

Industrial and Outdoor Applications

In harsh environments, prioritize enclosures that offer superior resistance to moisture, chemicals, and physical impacts. Anodized aluminum's durability makes it an excellent choice for such demanding settings.

Aesthetics and Design Considerations

Beyond functionality, the enclosure should align with the project's visual requirements. Customization options for colors, finishes, and branding can contribute significantly to the overall design.

Conclusion

Choosing the best anodized aluminum enclosure for your project involves a meticulous evaluation of project-specific needs, material quality, customization options, and application requirements.

By considering these factors and drawing inspiration from successful case studies, you can confidently select an enclosure that not only safeguards your project but also elevates its functionality and aesthetics.

By considering these factors and drawing inspiration from successful case studies, you can confidently select an enclosure that not only safeguards your project but also elevates its functionality and aesthetics.