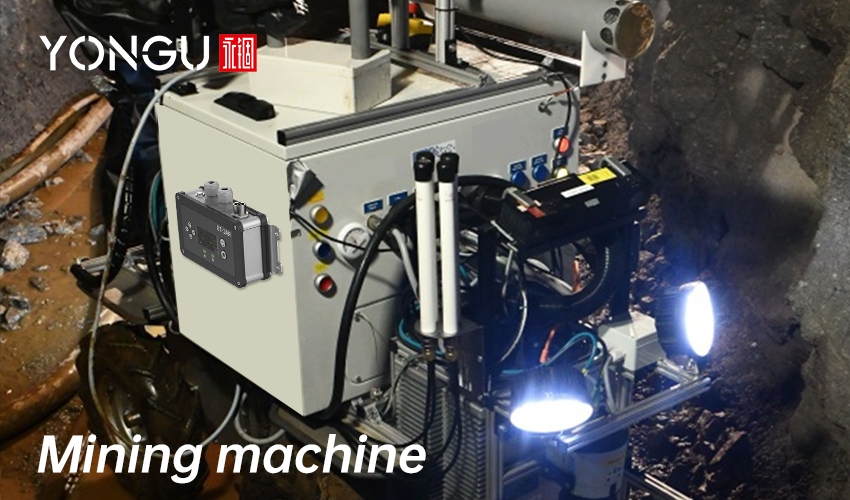

Many electronics firms are designing items for use in mines as the mining sector continues to grow. But in most mines, the climate is exceptionally hostile to electrical devices, and a well-built enclosure is needed. One of the most excellent alternatives for the mining sector is YONGU aluminum electrical and electronic enclosures.

Ingress Protection

In the oil and gas industry, intrinsically safe enclosures are required. These enclosures must be able to regulate the flow of flames and sparks to minimize the risk of fire.

Ingress protection and methods to safeguard the electronics contained within the enclosure, on the other hand, are of paramount importance for the majority of mines. Ingress protection is a term used in the electronics industry to describe the ability of an enclosure to protect its contents from dust and water.

IP66-rated enclosures are watertight and dust-proof, making them ideal for outdoor use. IP68 sections, designed to withstand the extreme conditions of mines, may be submerged in water and allow the electronics within to withstand floods and waves. (here can referring to our previous articles: IP65 VS. IP68 Enclosure Ratings: which one is the best?)

While it may appear that creating a water and dust-proof enclosure is a straightforward task, things may get tricky when the electronics systems within demand require typical features like power and data cabling, user interfaces, and displays.

All enclosures must meet NEMA 4X or 6P requirements. With this specification, a lot of dirt, dust, and water may be handled by enclosures that can be utilized underground. The components within are protected from the outside environment due to the enclosures.

Material

There are a wide variety of materials available for enclosures, as well as a variety of applications. There may be an emphasis on corrosion-resistant materials in gold mines, for example, because of the harsh chemicals employed in extraction.

For safety reasons, it is critical that miners can readily communicate and supervise activities. The use of aluminum in the building of explosion-proof enclosures is a common practice across the world.

For most applications, corrosion resistance makes this material the most valuable and flexible option.

The reduced weight of aluminum makes it easier to assemble and maintain the system than cast iron. This material has high corrosion resistance without having to be galvanized or varnished on the surface, like cast iron, which needs to be galvanized and varnished to protect it from the elements.

Furthermore, it is less expensive than stainless steel.

When it comes to explosion-proof electrical protection, the mechanical qualities of aluminium alloy injection molds are highly suitable for the application. Drilling holes for cabling or making other particular changes is not difficult with aluminum electrical enclosures.

Tailored Mechanisms

Eronics used in mines present a significant challenge when it comes to the management of cooling and heating in a system, and there are many different enclosure mechanisms available to reduce the amount of heat that is generated by the electronics themselves as well as the amount of heat that is generated when the electronics are exposed to the sun.

Due to its use in the mining sector, there is a broad range of variation in both the temperature and the level of exposure that may be experienced within an enclosure. Some outdoor enclosures are subjected to the sun's scorching heat for longer timeframes, while others are located in areas where the temperature is consistently cold beneath. Enclosures can endure all of these fluctuations and preserve the equipment contained within them based on the needs of the application and the equipment. An enclosure should, in most cases, have natural Ultraviolet tolerance, which indicates that it is not affected by the sun and can also endure temperatures as high as 265 degrees or as low as far below freezing.

Insulation and filtered fans are two additional crucial features of mining enclosures, which help keep electronics cool and dust from entering.

A sun cover and a slanted roof are both possible functions of dampers in some instances. Sloped roofs are a must in mines because they keep dust from building up and make cleaning a breeze. This is especially critical in coal mines, where combustible dust can pile up and pose a danger.lect

Shock And Interference

In addition to heat, dust, and humidity, vibrations and electromagnetic interference are other typical hazards on mine sites that may significantly impair the life of electronics.

It is recommended that electrical enclosures be capable of withstanding mechanical stress of more than 900 pounds. It is essential to be able to resist the impact or vibration caused by an explosion or being exposed to falling debris to work safely in the potentially dangerous environment of a mine. Therefore, mounting solutions have to be suited for underground installations and ought to have the capacity to absorb vibrations and shocks that could take place.

When designing enclosures for mining equipment, electromagnetic compatibility is one of the most critical design considerations, especially in communication and transmission. Mining enclosures will often feature EMC O-RINGS to combat this issue; nevertheless, the wall thickness of our enclosures is also an important consideration.

In addition, many of the systems in mines are stationary systems; nevertheless, for the electronics that are mounted on plant equipment or vehicles, shock-absorbent mount systems are an absolute necessity in the enclosure. The requirements of the client dictate this.

Other Factors to Consider

Chemical-resistant enclosures can protect personnel and their equipment from dangerous contaminants. Equipment can be damaged by various factors such as pressure and chemical concentration. When creating a safe enclosure, businesses should also consider the following aspects.

Mining equipment uses a variety of electronic enclosures, and no matter how flexible the design, there isn't a one-size-fits-all answer.

Enclosures may be designed and engineered to safeguard high-value equipment on a mining site by thoroughly analyzing the environment, potential differences, and equipment needs. Working in a mine is risky, as is ensuring the safety of both the equipment and the miners themselves.

YONGU IP68 WATERPROOF ALUMINIUM BOXES

YONGU IP68 Waterproof Aluminium Boxes & IP67/IP68 enclosures are suitable for use in harsh environments such as heavy machinery, industrial plants, and underwater or outdoor applications.

YONGU has a wide variety of IP-rated enclosures with flexible customization options. If you're looking for IP68 enclosures, we're proud to offer several models, including:

YONGU L Series: Durable enclosures rugged enough for indoor or outdoor applications

L Series include around 24 different models, including

- Outdoor Electrical & Water Proof Boxes

- Waterproof Plastic Enclosures

- Waterproof Electrical Enclosures

- IP67 Aluminum Boxes

- Waterproof Electrical Junction & Power Boxes

- Weatherproof Electrical Enclosures

- Waterproof Metal Junction Boxes

- Waterproof Box for Boat

- Waterproof Battery Boxes

- Automotive Waterproof Electrical Junction Boxes

- Waterproof Connection Boxes

- Waterproof PCB Boxes

- Waterproof Switch Boxes

- Waterproof Underground Electrical Junction Boxes

- Rugged and robust for heavy-duty use.

- Maintaining waterproof and dust-proof functioning is made more accessible by using a distribution ring.

- Diecast aluminum housing that is resilient to shocks

- The unfinished interior surfaces can be used to achieve conductivity

YONGU M Series: Highly versatile enclosures at an economical price

M Series include around 11 different models, including

- IP67/IP68 Aluminum & Waterproof Boxes

- weatherproof electrical boxes

- outdoor electrical junction boxes

- waterproof junction boxes

- outdoor electronic boxes

- Rugged and robust for heavy-duty use.

- Maintaining waterproof and dust-proof functioning is made more accessible by using a distribution ring.

- Diecast aluminium housing that is resilient to shocks

- The unfinished interior surfaces can be used to achieve conductivity

You can also contact us at +86 13326782625 or write us [email protected].