Technical drawings are still necessary even though CNC machining is helping to automate manufacture. If you develop technical drawings accurately, they help speed up and streamline your manufacturing project.

WHAT ARE TECHNICAL DRAWINGS?

Technical drawings are documentations that include every single 2D design that is specific to the part that you intend to build. By showing details that can be difficult to portray, such as internal and exterior threads, various surface finishes, annotations, dimensions, and tolerances, they provide a clear perspective of the parts.

You may be curious about the design process steps if you are currently developing a product you want to manufacture and sell. Understanding product design concepts and research come first.

Product Design Ideation or idea

An idea for a product is born out of a dilemma you recognize and solve. The idea for a particular product resides only in your head, even though you've thought it through and have an idea of what it would look like. If you've reached this point, you must write down your thoughts. If you're not good with a pencil and paper, use a notepad and pen to jot down ideas and details. To do this, you should try to distil your concept down to its core goal, the issue you hope to address, and the form you hope it will take. Make a note of the colour, texture, and appearance you desire. Communicating your idea on paper is the first step to bringing your product to life.

Product design research

If no one else has already worked on this topic, it's time to move on. An easy place to begin is with a quick search on Google. Use image search or seek firms that offer comparable products to find what you're looking for. Check and double-check your fresh concept to see whether it's already out there before you invest time and money in implementing it.

Using these drawings, machinists will have an easier time understanding your manufacturing project, they will be able to provide more accurate cost estimates for production, and the risk of errors occurring during manufacturing will be reduced.

COMMON TECHNICAL DRAWINGS FORMATS

A variety of formats are available depending on the stage of development or the amount of information required for your physical product idea.

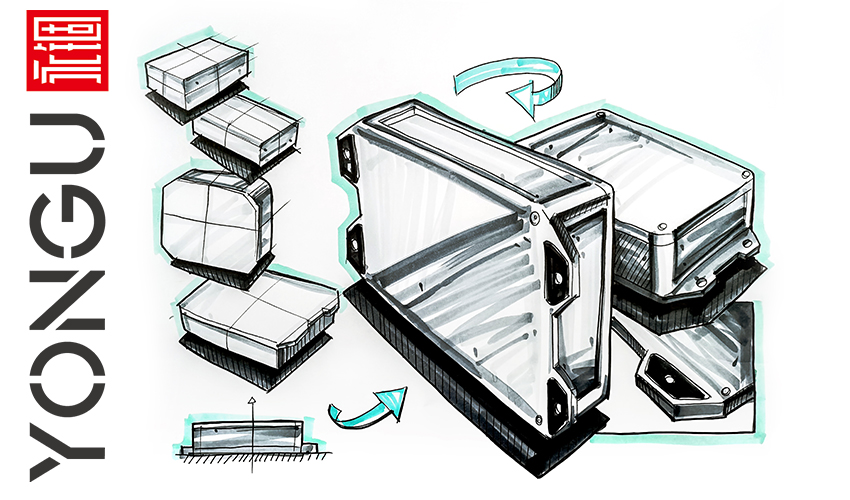

Design Sketches

Starting with design sketches is one of the most straightforward ways to start. On the other hand, they are not just hastily drawn sketches on paper. Integrity and detail on design drawings are critical to their usefulness in the development and production process.

You need to include the following in this initial level of depth regarding your idea:

- Aesthetic appeal that conveys a product's intended look and function visually.

- Product and component materials.

- General measurements of the product to be used as a reference for making a mock-up.

- Functions that aid in the better understanding the structure of a machine or its parts are described in this section.

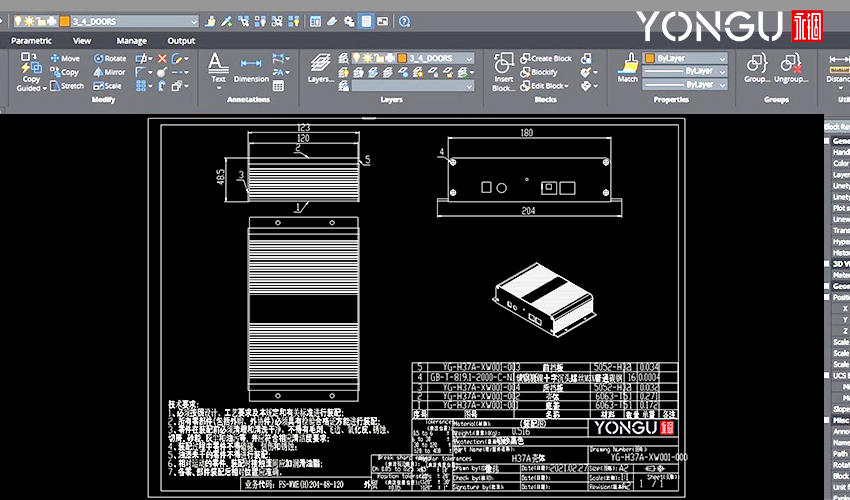

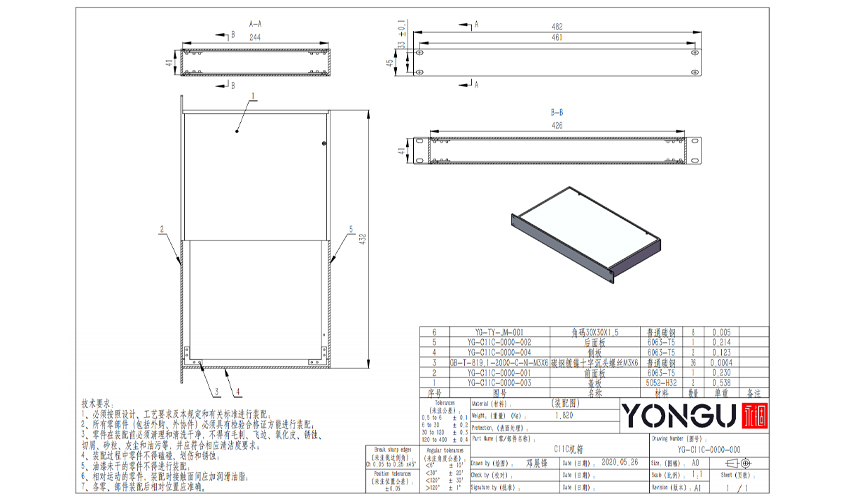

2D Drawings

The majority of technical drawings are drawn in 2D. With most soft products, 2D patterns may be used to manufacture portions and layers of the product.

Two-dimensional drawings are typically depicted the following:

- Various perspectives, including front, back, side, top, bottom, sectional, and geometric views, have been established so that users can access any part of the object.

- It's the specific type and quality of the material. Additional details like paint or a protective coating are also included in the design.

- The sketch is a template for most of the product's measurements and characteristics. If you have a product with many moving parts, you need to pay attention to the measurements of the components.

- There should be a range of tolerances for all dimensions, especially those deemed crucial. While the manufacturing method often determines the tolerable tolerance range for a particular product, the product's shape also has an impact.

This is the most frequent sort of format used today, and it's generally necessary to be able to produce the product and its components utilizing machines with the help of CAD models.

Here's what CAD models can tell you in the most basic terms:

- You may see the product in any configuration and in real-time using a CAD program. You may also generate photo-realistic renderings of your 3D model from 3D models.

- Although the model does not explicitly state dimensions, you may precisely measure any dimension in the model.

- CAD models allow you to see where components are situated and how they fit together in a product.

- The ability to run virtual simulations is a powerful and valuable feature of CAD models as it aids in different kinds of tests for product reliability in reality.

This only applies if your product contains Printed Circuit Boards Assembly, and electronic boards. Similarly, a 2D design of the boards' size and materials will also be employed.

Given electronic files, on the contrary, a side will be created to explain graphically the logic of how electronic components interact with one another to accomplish a specific purpose.

They don't depict the product's aesthetics so much as they indicate how it should work. The following are the components of an electronic schematic:

- The diagram makes use of symbols to depict the many electrical components, including but not limited to resistors, capacitors, switches, transistors, and integrated circuits, amongst others.

- In a schematic diagram, wires and terminals illustrate how components are connected in the circuit.

- There is a voltage level assigned to each component in the system.

TECHNICAL DRAWINGS MUST INCLUDE

An ideal technical drawing mitigates all of these challenges, and it must contain the following parts:

Title Block

When looking at the technical drawing, the title block is in the bottom right corner. There is a lot of essential information about your product in this design, such as the name of the item, part number, drawing number, and your firm.

Different components' signatures and approval dates are also included in the title block. The machinist will find this information to be quite helpful since it offers information on the designers who worked on the various components. It also identifies the individuals responsible for creating and verifying the production drawings.

Orthographic Views

Two-dimensional orthographic views are a way to show your anatomy from numerous perspectives, such as from the front or rear. Your product geometry, dimensions, and tolerances are conveyed in these displays.

Isometric View

Your component is shown in 3D on a 2D surface using an isometric perspective. To make your portion look like it's being viewed from above, rotate it 45 degrees around the vertical axis and 35 degrees horizontally. This view is recommended.

Section view to help the machine shop comprehend your part's shape and installation direction.

A segmented view is a two-dimensional picture of your part when split in half. Allows for the discovery of previously overlooked aspects or characteristics.

Note to Manufacturer

Technical drawings typically incorporate notes to convey information or requirements that aren't explicitly included in the picture. The technician might, for example, break and deburr all of your part's sharp edges or use a specific finishing procedure on some of its features.

You will be able to submit your product to a fabrication facility or a manufacturer after you have a set of technical drawings for it. However, before it can go into production, the design must consider several factors.

To guarantee that a concept is ready for fabrication, a process known as Design for Manufacturing necessitates a technical evaluation and a grasp of the fabrication process.

YONGU UNIQUE CUSTOMIZATION SERVICE

YONGU can assist with the design and construction of an electronic product. CAD tools are used to generate an optimal design once an application study is completed.

Designing The Unique Prototype

The prototype design is one of YONGU's services, and we can help you with it. We are a supplier of both ODM and OEM goods. Please get in touch with us if you need help designing a prototype that stands out from the rest of the pack.

- Use the internet to communicate your box specifications.

- Create a prototype with a distinct appearance and structure.

- Freely alter the design till you're happy with it.

- Ensure that the aluminium case fulfils your requirements by offering a sample service before placing bulk orders.

Engineering The Best Solutions

The engineering of the most efficient solutions is one of YONGU's specialities. If you have an idea in mind, we'll turn it into a working prototype or a run-of-the-mill production run.

- Your 3D model, CAD file, and hand-drawn drawing will be transformed into a substantial piece of work that we can manage and validate with you.

- The 3D and CAD design files for our existing products are available to you so that you may make changes to them.

- Once we have a concept from you, we'll take care of the rest.

- A wide range of practical solutions for PCB boards, the core structural components of electronic gadgets, are available from our extensive assortment.

Processing The High-Quality Products

YONGU offers high-quality box processing as one of its services. Distinctly enable accurate supply networks rather than concentrating on developing frictionless technologies. High-precision and high-quality aluminium enclosure will be delivered to you.

- Detailed explanations of the manufacturing process.

- Using CNC machines, aluminium boxes and other products are made.

- Designing, building, and testing with the highest quality possible.

For further information and customized product of your requirements, please follow our FACEBOOK for more updates and informations.

You can also contact us at +86 13326782625 or write us [email protected].