The rapid advancement of nanotechnology has led to a flourishing of the electronic industries, which has led to the electronic systems being densely crowded with electrical components within the instrument. It is a direct result of the growth of the electronic industries. This unprecedented expansion of electronic, telecommunication, and instrumentation technologies has resulted in the production of a novel form of pollution known as electromagnetic interference, a completely undesirable byproduct.

TYPES OF EMI

There are two distinct categories of EMI.

Narrow-band EMI

The fact that it occurs over a discrete frequency makes it familiar for radios, TVs, and cell phones to experience this problem. It's as though the signals are being mixed up, and the gadgets are beginning to fail. The average consumer can usually ignore disruptions that do not harm equipment.

Broadband EMI

It is present throughout a broader spectrum since it occupies a significant portion of the electromagnetic spectrum. The sort of electromagnetic interference (EMI) known as broadband EMI is the kind of EMI that poses the most risk to the gadgets you use.

When you utilize equipment with a digital data link, you will typically become aware of this form of interference. EMI can be caused by something as innocuous as a motor brush that has become worn out. EMI can be shown by a fluorescent light that has flaws. EMI can be generated when you turn on your vehicle's ignition. The igniter of a jet engine is a potential source of interference due to its similar electromagnetic properties. In addition, interference can be caused by defects in the power lines themselves.

A wide range of emitted frequencies could be received by the devices you're attempting to use in each scenario. One of the most common types of interference in the electromagnetic spectrum occurs when signals at different frequencies interfere with one another. Circuits, electrical lines, lighting, and even motors and engines emit energy that interferes with each other.

ELECTROMAGNETIC INTERFERENCE (EMI) SHIELDING

EMI Shielding

It is the use of materials and manufacturing processes to protect communications from being disturbed by electromagnetic signals, as well as from interference with other components in modern gadgets and equipment.

Importance of EMI Shielding

Electromagnetic interference (EMI) can potentially interrupt essential electronic devices, equipment, and networks. A few examples include medical and defense technologies, mass transportation systems, automotive touch displays, and GPS technologies, to mention just a few.

Conductive and radiated EM signals are known as EMI. The effects of electromagnetic interference (EMI) are not restricted to the malfunctioning of electronic devices; instead, they can affect human health. For instance, prolonged exposure to electromagnetic radiation raises the chance of developing cancer, breathing problems, cardiovascular disease, migraines, and even miscarriage.

Many factors contribute to electromagnetic interference, including both human and natural ones. Temporary disruptions and data losses might lead to system breakdown and even death.

Electromagnetic energy (EME) in the application domain might produce interference, and engineers must be aware of this. Your gaskets may not adequately protect against electromagnetic fields in the RF spectrum, which has frequencies between 3kHz and 300GHz. If you don't have this fundamental EMI understanding, you may design gaskets that do not adequately protect against electromagnetic fields in the RF band. Wireless communications can be disrupted by RF waves, the foundation of radio technology.

EMI Shielding Working Principle

Efficient EMI Shielding's primary goal is to protect sensitive devices from electromagnetic interference. A metallic screen absorbs the electromagnetic interference that is passed via the air. It works like a Faraday cage, where the metallic screen fully encircles the sensitive electronics or the transmitting electrical components. An electric current flows across the screen as it takes in broadcast signals and amplifies them. A physical ground plane or a ground connection must be used

to absorb this current. These sent impulses must be absorbed before they can reach the sensitive electronics to keep the shielding as efficient as possible.

Smartphones are an excellent illustration of this. EMI shielding must be utilized to safeguard the sensitive electronics in the instrument that processes and portray information from the transmitter of the phone.

ASPECTS TO BE TAKEN INTO ACCOUNT IN THE DESIGN OF SHIELDED ENCLOSURES

Material & Corrosion

- Pre-tin plated steel

- Copper alloy 770

- Copper

In comparison to other alloys or pre-tin-coated steel, copper is more expensive. But because of its increased conductivity, it is an excellent EMI shield.

- Aluminum

EMI shielding is available in various forms, with mesh being the most popular and commonly utilized. An aluminum-coated version of the adhesive strip can also be purchased if desired.

The Thickness of Enclosure Material

For frequencies exceeding 1 MHz, a thickness of 0.01mm should be sufficient. When coping with eddy currents at lower frequencies, including 30 kHz and below, one must employ materials with strong magnetic and electric conductivity, and thicker material may be required.

For instance, a 6 mm-thick material is used to build an EMP military bunker. The retardation in these bunkers is 80 decibels, which protects against frequencies as low as 10 kHz. Mu-Ferro and thick metal layers are recommended for shielding frequencies about 50 Hz from transformers, which might pose health dangers or affect the operating systems of equipment.

Prevent Gaps in Enclosures

Gaps in the enclosure should be avoided at all costs; however, this is critical at frequencies beyond 5 kHz. Small holes in the enclosure can cause severe problems at high frequencies, especially those between 100 MHz and 40 GHz. There should be more focus on shielding holes and gaps at higher frequencies. Gaskets that are malleable and pliable are ideal for this application. The gasket should maintain continuous electrical contact with the enclosure with modest tensile stress while providing good conductivity.

As a general rule, the greater the frequency, the more critical it is to keep your shield free of holes or gaps. The use of soft and flexible gaskets might be beneficial in some instances. The distance between the fasteners and the structure's stiffness determines how stiff your gasket should be. Instead of avoiding gaps, a stiff gasket might cause doors, lids, or panels to deflect and leave holes in the sealant. The enclosure no longer shields higher frequencies.

Tolerances determine gasket thickness and material selection in the enclosure or panel fabrication process. To begin, the conductive layer located on the exterior of the gasket must have the same galvanic range as the materials that are used in the building of the enclosure. Galvanic corrosion impairs electrical conduction and shielding efficacy.

In short, an enclosure should provide the following

- Anticipate and satisfy the prerequisites for immunity.

- Use screening, grounding, and shielding to isolate the problem circuits.

- Increase the resistance of devices to sensitive circuits to de-sensitize them.

- Develop an EMI Essential that is uniquely yours.

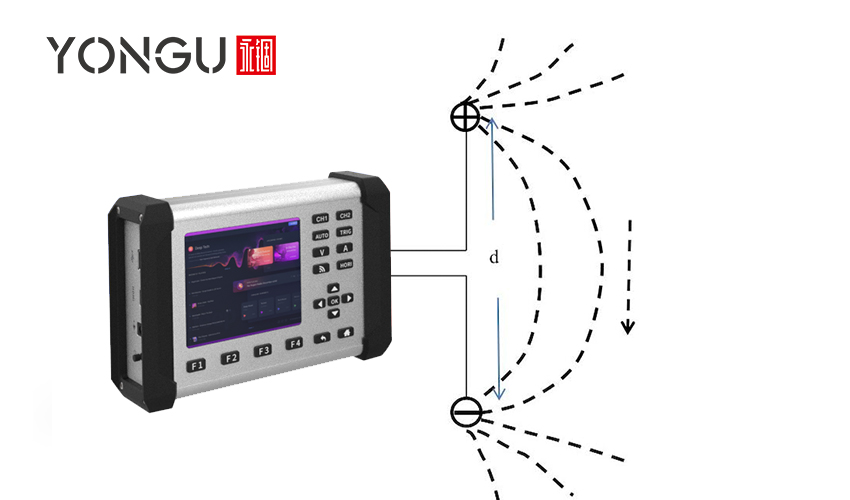

A wide variety of aluminium enclosures are available from YOUNGUBOX, including traditional designs for the factory floor and cost-effective boxes. Because of its slight weight and high durability, aluminium is a popular choice for portable enclosures.

These factors along with IP65 and other protection services offered in YONGU sheet metal boxes, make them suitable for EMI protection.

YONGU has two kinds of sheet metal enclosure boxes that are entirely customizable in every dimension.

- YONGU Sheet Metal Box E Series

- YONGU Sheet Metal Box S Series

- Sheet metal box, aluminium bending.

- New and beautiful appearance, which can be used on a desk.

- The feet make the equipment place more stably.

- The overall structure is beautiful and stable.

- Different colors can be customized.

- Customizable Thickness & other dimensions

- Customizable Dimensions, hole drilling, surface treatment & printing

- Flexible can meet customers’ requirements

- Good quality aluminium material al5052

- It can be used as a battery case

- It can be used as Custom Computer Case

- It can be used as a Lithium Battery Box

- It can be used as Electrical Enclosures

- It can be used as metal cases for electronics

- It is suitable for Aluminum Electronic Project Box

- Raspberry Pi 4 Case

- Feasible Sheet Metal Fabrication

For further information and customized product of your requirements, please follow our FACEBOOK for more updates and informations.

You can also contact us at +86 13326782625 or write us [email protected].