Exposure to the elements, contact with hazardous liquids, or explosive atmospheres are examples of potentially dangerous settings. Wiring can be corroded or damaged by exposure to the environment and strong chemicals. Junction boxes provide additional safety from unauthorized wire tampering.

JUNCTION BOX BASICS

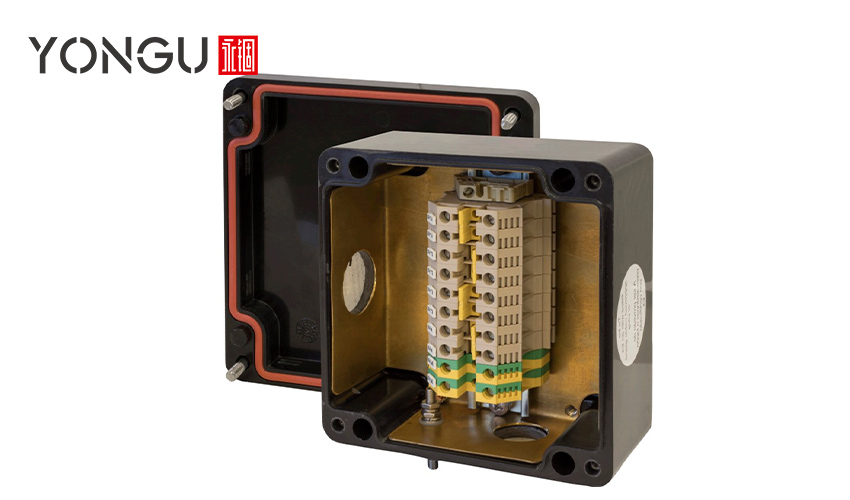

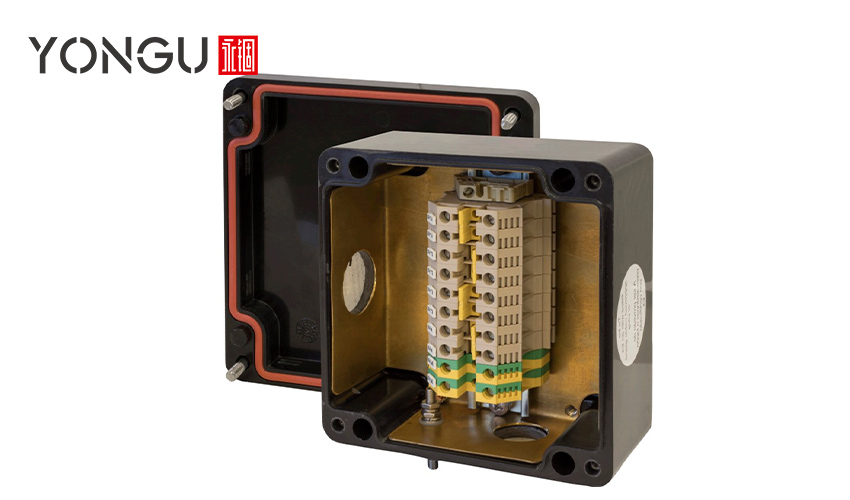

Junction boxes distribute electricity from a central source to several outlets by housing the necessary wire connections. A junction box may house a single power source connected by multiple lines to power several lights.

IMPORTANCE OF JUNCTION BOX

Junction boxes have a significant role in residential and corporate contexts; the most important ones are described here.

- It is essential to have junction boxes to provide housing for electrical wiring located outside, as this is an environment in which natural factors like rain can cause electrical risks if the wires are allowed to become wet. People are kept safer as a result of the fact that the shell of most junction boxes is impermeable and durable enough to prevent water from penetrating and reaching the wires contained within.

- Protecting junction boxes against burglary, which occurs more frequently than some people are willing to accept, is an essential function of junction boxes. As a result of the fact that they are constructed using metallic materials, electrical components are an easy target when they are left in open surroundings. Junction boxes are built out of sturdy materials that may be locked, making it difficult to break them in any way.

- The use of junction boxes allows for the tidy installation of electrical wire to make it simple for people to understand where everything leads and the kind of current carried by the cabling. Because of this, it is simple enough for anybody to use, and there is no possibility of electrocution.

- If something goes wrong without any prior notice, one may rely on the safety measures that junction boxes are equipped with, such as grounding and emergency switches. If an accident involving electricity occurs, one who is prepared with main controls, for instance, can promptly cut off the electricity in the building.

MATERIALS USED TO CONSTRUCT JUNCTION BOXES

Typically, metal or sturdy plastic is used for junction boxes. Whether or not the junction box is expected to hold weight dictates whether or not it should be made of plastic. Plastic junction boxes can't handle the weight of light fixtures, while metal ones can. Plastic junction boxes are often installed more quickly and with less effort than metal ones. However, one can use metal or plastic for a typical junction box that serves to conceal wire splices.

A variety of materials are used to construct junction boxes, the most common of which are steel, stainless steel, aluminum, and plastic reinforced with fiberglass.

Stainless steel would be the material of choice for the construction of an instrument junction box utilized offshore. Stainless steel of grade 316L would be employed in the production process because of its superior strength and corrosion resistance.

Aluminum enclosures are appropriate for usage in environments that need high levels of ruggedness and chemical resistance. The fields of electrical engineering, mechanical engineering, seafaring, electrolysis, and the petrochemical industry are where it is most commonly utilized.

A variety of materials are used to construct junction boxes, the most common of which are steel, stainless steel, aluminum, and plastic reinforced with fiberglass.

Stainless steel would be the material of choice for the construction of an instrument junction box utilized offshore. Stainless steel of grade 316L would be employed in the production process because of its superior strength and corrosion resistance.

Aluminum enclosures are appropriate for usage in environments that need high levels of ruggedness and chemical resistance. The fields of electrical engineering, mechanical engineering, seafaring, electrolysis, and the petrochemical industry are where it is most commonly utilized.

When it comes to constructing an instrument box for outdoor use, the material of choice would be glass fiber reinforced polyester. For it to be able to withstand the various climatic conditions, selecting this material will help us avoid rust. These containers would have a solid endurance to high ambient temperatures without affecting their yield. In addition to having a long life expectancy and outstanding mechanical qualities, the glass fiber reinforced polyester has a high resistance to contamination from oils. It is one of the many benefits that this material offers.

RATINGS FOR JUNCTION BOXES

NEMA Junction Box Ratings

NEMA-rated junction boxes are "enclosures" that are typically constructed for use either indoors or outdoors and provide a heightened level of protection against accidental contact with the electronic devices that they house. They offer some degree of protection against the circulating dust, fiber, and fluff, in addition to some degree of protection against the splashing of light liquids.

A NEMA junction box's rating is a number between 1 and 13. Due to the non-progressive nature of this rating system, higher ratings do not automatically receive the benefits of lower ratings. In contrast, each value stands for robustness against a particular pool of environmental threats. Additional levels of protection are indicated by letters such as S, X, and R.

IP Junction Box Ratings

IP ratings, which stand for "Ingress Protection," describe the amount of protection that a junction box provides for its users against a variety of variables, such as water and foreign objects, that might potentially harm the electrical components. Users are shielded from any hazardous interior workings as well.

The ingress protection, or IP rating, of a junction box, is used to measure the amount of protection provided by the box, such as its ability to keep liquids and solid objects from entering an enclosure. The terms "debris," "dust," and "body parts of personnel" are all considered to be "solid things." This context considers moisture, water, and oils to be liquids.

UL Listed Junction Box Ratings

Underwriter Laboratories is the name of the independent safety certification organization that was founded in 1894 and goes by the acronym UL. UL is responsible for establishing safety and quality standards for a variety of products, including industrial control panels and junction boxes that contain high voltage equipment.

One can determine with this information whether or not a specific junction box can be employed in the environment that is being discussed.

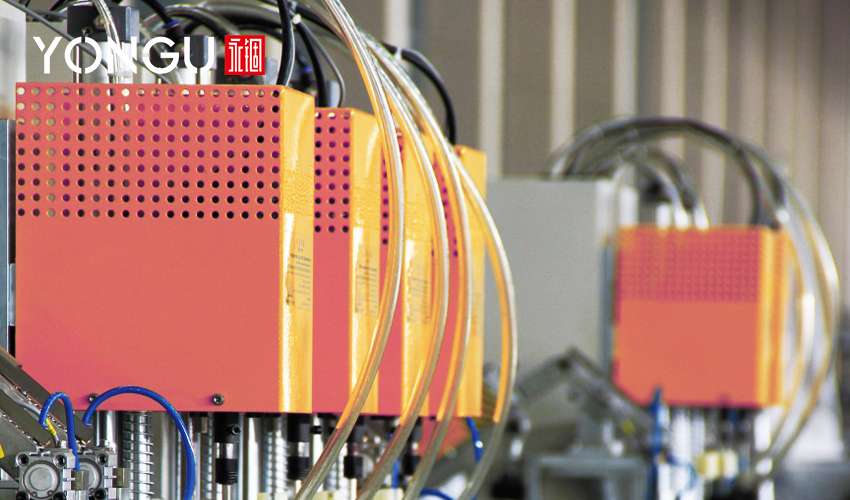

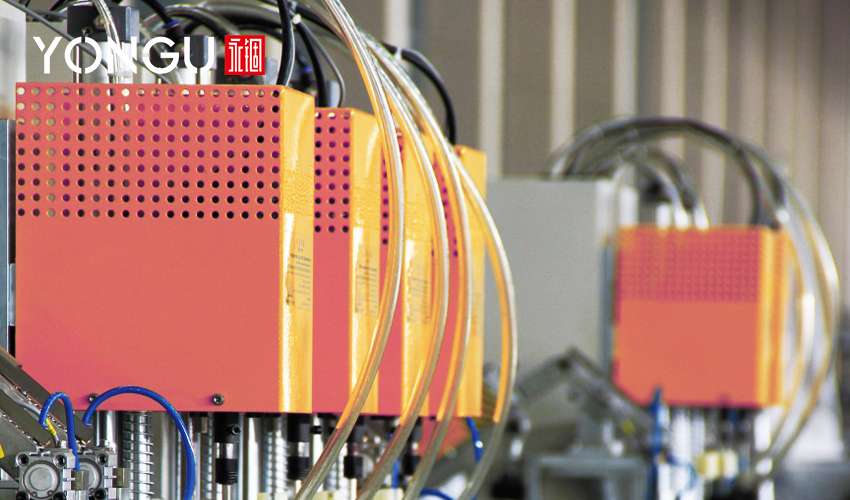

YONGU JUNCTION BOX

If you are looking for a junction box or need help locating the appropriate one, we are here to assist you in locating the optimal option. YONGU can successfully achieve the lead times that you have specified since they build and design excellent junction boxes according to your precise specifications.

In addition, we feel that if we take care of your unique junction box demands when you are setting the components that go into it, we will save you not just money but also time and the irritation of having to deal with such problems.

YONGU offers customizable junction boxes, including

Each of the above junction box models is designed based on the market and customer needs with salient features including flexibility, toughness, robustness, waterproof and dustproof functionality, shock resistance, conductivity, and customizable shape, size, material, and configuration.

For further information and customized product of your requirements, please follow our FACEBOOK for more updates and informations.

You can also contact us at +86 13326782625 or write us [email protected].

RATINGS FOR JUNCTION BOXES

NEMA Junction Box Ratings

NEMA-rated junction boxes are "enclosures" that are typically constructed for use either indoors or outdoors and provide a heightened level of protection against accidental contact with the electronic devices that they house. They offer some degree of protection against the circulating dust, fiber, and fluff, in addition to some degree of protection against the splashing of light liquids.

A NEMA junction box's rating is a number between 1 and 13. Due to the non-progressive nature of this rating system, higher ratings do not automatically receive the benefits of lower ratings. In contrast, each value stands for robustness against a particular pool of environmental threats. Additional levels of protection are indicated by letters such as S, X, and R.

IP Junction Box Ratings

IP ratings, which stand for "Ingress Protection," describe the amount of protection that a junction box provides for its users against a variety of variables, such as water and foreign objects, that might potentially harm the electrical components. Users are shielded from any hazardous interior workings as well.

The ingress protection, or IP rating, of a junction box, is used to measure the amount of protection provided by the box, such as its ability to keep liquids and solid objects from entering an enclosure. The terms "debris," "dust," and "body parts of personnel" are all considered to be "solid things." This context considers moisture, water, and oils to be liquids.

UL Listed Junction Box Ratings

Underwriter Laboratories is the name of the independent safety certification organization that was founded in 1894 and goes by the acronym UL. UL is responsible for establishing safety and quality standards for a variety of products, including industrial control panels and junction boxes that contain high voltage equipment.

One can determine with this information whether or not a specific junction box can be employed in the environment that is being discussed.

YONGU JUNCTION BOX

If you are looking for a junction box or need help locating the appropriate one, we are here to assist you in locating the optimal option. YONGU can successfully achieve the lead times that you have specified since they build and design excellent junction boxes according to your precise specifications.

In addition, we feel that if we take care of your unique junction box demands when you are setting the components that go into it, we will save you not just money but also time and the irritation of having to deal with such problems.

YONGU offers customizable junction boxes, including

- Terminal Junction Box

- Automotive Waterproof Electrical Junction Box

- Waterproof Metal Junction Box

- Waterproof Underground Electrical Junction Box

- Waterproof Electrical Junction Box

- Plastic Junction Box

- Waterproof Junction Box

- Outdoor Electrical Junction Box

- Custom fabricated electrical enclosures, boxes, and cabinets.

Each of the above junction box models is designed based on the market and customer needs with salient features including flexibility, toughness, robustness, waterproof and dustproof functionality, shock resistance, conductivity, and customizable shape, size, material, and configuration.

For further information and customized product of your requirements, please follow our FACEBOOK for more updates and informations.

You can also contact us at +86 13326782625 or write us [email protected].