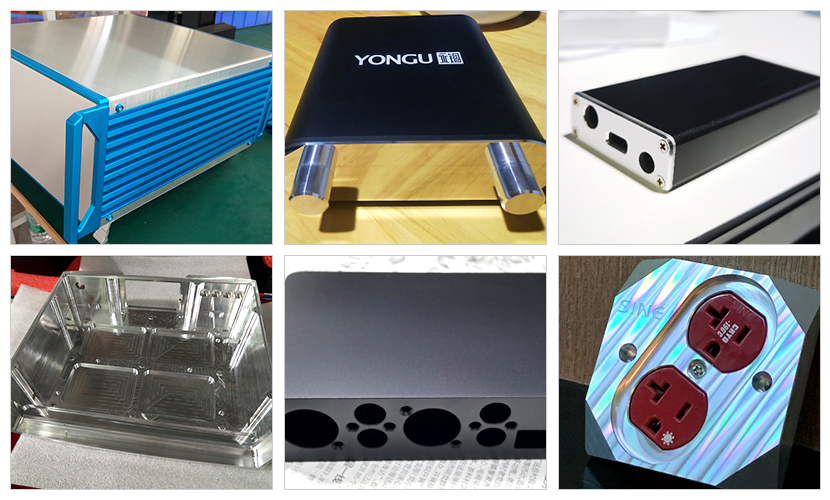

YONGU maximizes cutting-edge technology to ensure that our products meet or exceed the standards and become the top-leading aluminum profile producers in China and overseas.

The company has high standards, thus, opting for Computer Numerical Control (CNC) makes the work excellent. CNC has several applications, for example, flame or plasma cutting, forming, punching, laser cutting, and welding.

In this article, we will get to know what makes CNC machines very useful in manufacturing.

What does CNC mean? How does it work?

CNC stands for Computer Numerical Control. It is pre-programmed computer software that instructs the movement of factory equipment and machinery. Using a subtractive method removes unnecessary parts from a block of material.

Before CNC machines surfaced, the industry operates using manually controlled hand wheels or levers. CNC machines function using a language called G-code. This code tells them exact measurements for production such as feed rate, speed, location, and coordination.

A CNC machine makes durable, precise, and heat-resistant parts. Most industries use it because there is a range of applications for the technology. It includes casting, metal molding, jewelry, and more.

Using a CNC machine will surely impress you. It produces sturdy parts and precise dimensions. It is common in engines, airplanes, and machinery. You can find it in industries like engraving, lettering, and woodworking.

What are the different types of CNC?

1. Milling machines

It uses rotary cutting tools to sculpt components. It can create grooves, holes, shapes, slots, notches, pockets, and specialty faces.

2. Lathes

It produces cylindrical objects. It is a machine tool where the material or part is held in place and rotated by the main spindle as the cutting tool that works on it is mounted and moved on various axes.

3. Drilling machines

It drills holes in the workpiece. It has the accurate locating capacity of the position for drilling. These machines can also perform reaming, counterboring, and tapping holes.

4. Plasma cutters

It possesses a plasma torch used for cutting metals.

5. Grinders

It uses a rotary wheel to scour the material by grinding or grating it into the desired shape. It is easier to program than milling machines and lathes.

What are the Benefits of CNC Machining?

- Accuracy and consistent product quality: The process is more precise and repetitive. It minimizes time consumption. It reduces errors from the manufacturing process and gets rid of unnecessary waste.

- High production speed and increased efficiency: The process is automated. Therefore, it increases the speed and quality of manufacturing.

- Safety for Machine Operators: CNC machines work behind a transparent safety door. Hence, it is much safer than manually operated machines.

- More cost-effective: Manual machining would need one operator per machine. But this one would only require fewer machine operators. A skilled operator can already run several tools at the same time.

What products can CNC machines make?

CNC machines have vast applications that make them a much-preferred machine in different kinds of industries. Most engineers would surely agree to this.

Automotive and Transportation

CNC machines can make different parts of the following types of vehicles:

Automotive and Transportation

CNC machines can make different parts of the following types of vehicles:

- Automobiles: Parts for buses, cars, motorcycles, trucks

- CNC can automate the production of these parts.

- Trains: It cuts and shapes the robust exterior parts for public and private trains.

- Aerospace: Some parts of exteriors and interiors of aircraft and spacecraft are products of CNC machines.

- Marine: The external and internal components of many boat models come from CNC.

- Original Equipment Manufacturer (OEM)

OEM uses CNC machines in the metal fabrication process to produce a variety of components and product designs. - Prototypes: CNC possesses 3D and 2D capacities that make prototypes for parts and finished products.

- Mass production parts: This machine automates the production of some parts.

- Consumer Electronics and Other Products

High levels of accuracy during production are a must for electronics and other consumer products. CNC machines produce: - Electronic components: The machine cuts and shapes the sensitive metal parts allowing the electronics to function.

- Housing and enclosures: CNC can also make housing and enclosures.

- Appliance parts: There are heavier-duty parts that form reliable household appliances.

- CNC machines work with metal, plastics, and many other materials, thus contributing to multiple steps of consumer manufacturing.

Construction and Architecture

This modern machinery observes computer specifications to create: - Architectural elements: Architectural elements such as doors out of materials such as wood and metal can come from CNC.

- Pipes and railing: It can bend metal tubes and pipes for construction projects.

- Building models: CNC is also best in making detailed structuring models made from plastic and composite during the building design process.

Guangdong Yonggu Electronics Machinery Technology Co., Ltd has been in the industry for 17 years with ten years of aluminum eclosure export experience. Our customers widely use our product for digital communication, environment monitoring, security equipment, rail transit, and outdoor electronics. CNC machines are one of our advanced manufacturing partners that make our work more customer-friendly and more efficient.