Coating a printed circuit board assembly can be done with a conformal coating or potting and encapsulating resin. Chemical and heat resistance, as well as electrical insulation, are provided by these organic polymers, which protect the PCBA below. But that is about all they have in common with one another. This guide will explain how a PCBA responds to two types of coating, encapsulation resin and conformal coating.

CONFORMAL COATING

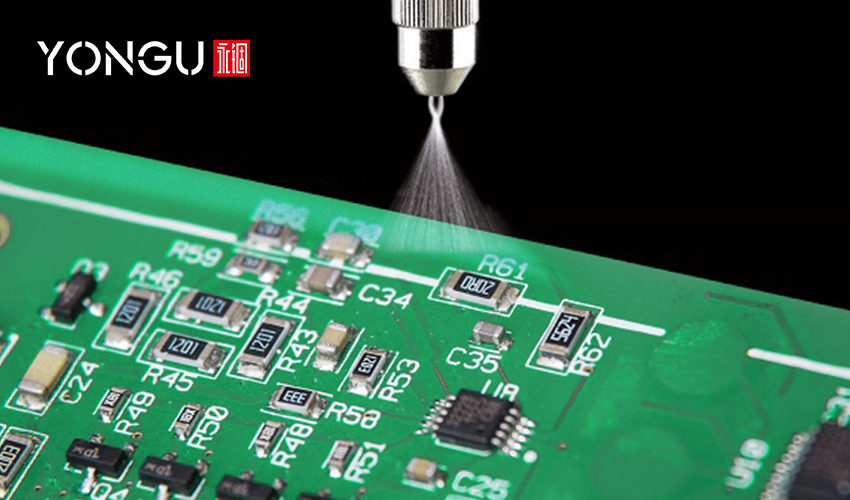

An electronic component or circuit board can benefit from a conformal coating, a dielectric layer that provides protection and conductivity.

Coatings that "conform" to the surface they are applied to (often referred to as the "substrate") protect without significantly increasing the device's overall mass or profile.

POTTING

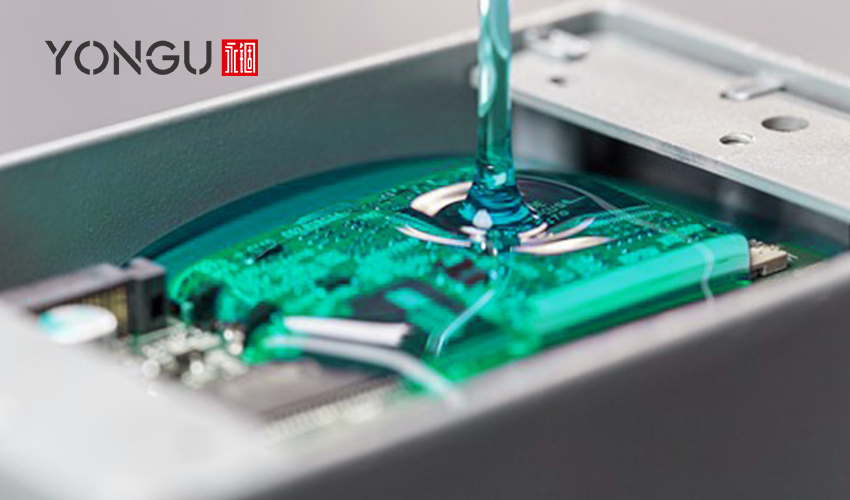

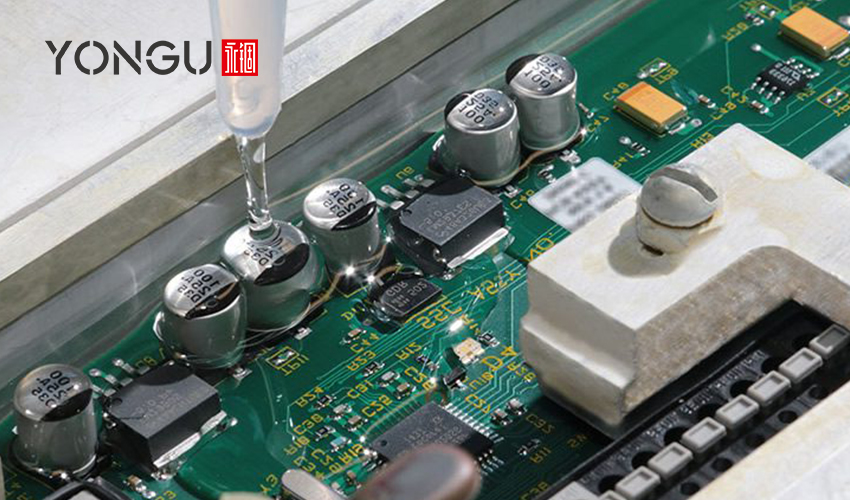

The purpose of potting, also known as embedment, is to shield a device from damage caused by its immediate surroundings. Instead of covering the board or gadget, potting encases it in a "pot" or shell.

After the substrate has been inserted into the pot, potting may commence. Once the pot is full, the gadget is submerged in a liquid compound. The liquid solidifies around the widget, thereby sealing it. The device and its housing are considered integral parts of the whole.

Printed circuit boards (PCBs) are commonly protected by potting, especially in high-volume manufacturing facilities.

WHETHER CONFORMAL COATING OR POTTING, WHICH PROVIDES BETTER PROTECTION FOR PCBA?

Many aspects of your product and how PCB resin coating and potting affect them must be considered to provide the most significant protection for your PCBA.

The selection of a shielding substance is heavily influenced by its surroundings.

The temperature outside the normal range might impact production, so it's essential to consider how resin can react when used in such conditions and how quickly or gradually the temperature might shift. When combined with its hardener, resin releases a great deal of heat, which might be harmful to the PCBA or the housing if it becomes too high.

Different conformal coatings have varying degrees of resistance to wetness. Resins are almost generally waterproof, but you should still check to make sure your layer is impermeable to water too. Resin can assist disperse the force of an impact, protecting the PCBA from potential damage if the component is subjected to severe physical shock.

High-velocity, high-volume settings, such as assembly lines and industrial equipment, can cause mechanical stress in the form of abrasion and scratches. The resin may be a thick barrier to stop the physical assault. If your PCBA is submerged or exposed to chemicals, resin and coatings will protect you.

Coatings enable greater design freedom and offer substantial protection for everyday items, such as consumer electronics, than PCBA potting. PCBA encapsulation usually is only necessary for devices used in extremely harsh conditions.

DESIGN FACTORS FOR CONFORMAL COATING & POTTING

Several design considerations influence the conformal coating vs. potting compound argument.

Putting a layer of resin on top of a surfboard makes it heavier because of the added thickness of the material. Heavier parts are only practical in some applications.

The structural rigidity of the resin makes it impossible for many goods to perform as intended.

In terms of the board's use, the resin is a hindrance because of its thickness and darkness, making it impossible to see through or remove for further alterations. Attempting to remove it may cause damage to the PCBA. However, coatings are often transparent, allowing you to see through them and make any modifications.

If the PCBA's housing doesn't provide enough protection, the resin might be a solution to add such protection. Protective coatings are commonly employed as an added layer of security in sturdy buildings.

In practice, one may be superior to the other for manufacturing purposes, depending on the specifications of the envisioned use. Resin is applied at a higher temperature and takes longer to cure, both of which pose risks. You may apply a conformal coating by hand, by brush, spraying it on, dipping the PCBA, or by utilizing a robotic system, and they dry relatively quickly.

Conformal coatings are a great alternative to encapsulation for protecting a PCBA from frequent dangers without adding extra weight and cost.

PROS AND CONS

Potting & Encapsulation

Assemble lines and other high-output production settings often choose for potting because they can be applied quickly and easily.

The increased strength and resilience over conformal coatings directly result from the thicker protection.

In addition to its other advantages, PCB potting also has the following features:

- Extreme durability against heat, chemicals, vibration, and the elements

- Enhanced resistance to wear and tear from impacts

- Improved resistance to moisture and electrical current arcs

- Potting compounds with darker shades add an extra layer of protection to any design.

- Simple and fast to operate, ideal for production settings

Putting a layer of resin on top of a surfboard makes it heavier because of the added thickness of the material. Heavier parts are only practical in some applications.

The structural rigidity of the resin makes it impossible for many goods to perform as intended.

In terms of the board's use, the resin is a hindrance because of its thickness and darkness, making it impossible to see through or remove for further alterations. Attempting to remove it may cause damage to the PCBA. However, coatings are often transparent, allowing you to see through them and make any modifications.

If the PCBA's housing doesn't provide enough protection, the resin might be a solution to add such protection. Protective coatings are commonly employed as an added layer of security in sturdy buildings.

In practice, one may be superior to the other for manufacturing purposes, depending on the specifications of the envisioned use. Resin is applied at a higher temperature and takes longer to cure, both of which pose risks. You may apply a conformal coating by hand, by brush, spraying it on, dipping the PCBA, or by utilizing a robotic system, and they dry relatively quickly.

Conformal coatings are a great alternative to encapsulation for protecting a PCBA from frequent dangers without adding extra weight and cost.

PROS AND CONS

Potting & Encapsulation

Assemble lines and other high-output production settings often choose for potting because they can be applied quickly and easily.

The increased strength and resilience over conformal coatings directly result from the thicker protection.

In addition to its other advantages, PCB potting also has the following features:

You can also contact us at +86 13326782625 or write us [email protected].

The structural rigidity of the resin makes it impossible for many goods to perform as intended.

In terms of the board's use, the resin is a hindrance because of its thickness and darkness, making it impossible to see through or remove for further alterations. Attempting to remove it may cause damage to the PCBA. However, coatings are often transparent, allowing you to see through them and make any modifications.

If the PCBA's housing doesn't provide enough protection, the resin might be a solution to add such protection. Protective coatings are commonly employed as an added layer of security in sturdy buildings.

In practice, one may be superior to the other for manufacturing purposes, depending on the specifications of the envisioned use. Resin is applied at a higher temperature and takes longer to cure, both of which pose risks. You may apply a conformal coating by hand, by brush, spraying it on, dipping the PCBA, or by utilizing a robotic system, and they dry relatively quickly.

Conformal coatings are a great alternative to encapsulation for protecting a PCBA from frequent dangers without adding extra weight and cost.

PROS AND CONS

Potting & Encapsulation

Assemble lines and other high-output production settings often choose for potting because they can be applied quickly and easily.

The increased strength and resilience over conformal coatings directly result from the thicker protection.

In addition to its other advantages, PCB potting also has the following features:

- Extreme durability against heat, chemicals, vibration, and the elements

- Enhanced resistance to wear and tear from impacts

- Improved resistance to moisture and electrical current arcs

- Potting compounds with darker shades add an extra layer of protection to any design.

- Simple and fast to operate, ideal for production settings

Conformal coatings take up far less room inside a device's housing than PCB potting. The thin coating imposes little mechanical stress on the base. As a bonus, PCBs with conformal coatings are easier to rework, repair, and check.

Although conformal coating has a few drawbacks, it won't be as resilient or long-lasting as PCB potting. It may result in inadequate defences against devastating hazards. However, manufacturers that want to take advantage of conformal coating's benefits can choose from various materials.

YONGU CUSTOM DESIGN SERVICES

The term "modern industrial design" refers to a broad field that encompasses a variety of subfields, such as the design of products' functional aspects, structural aspects, forms, and packaging. Industrial design encompasses mechanical design, visual communication, architecture, interior design, environmental art design, furniture, product design, etc.

Industrial design involves thinking about more than just how something looks and works; we also have to consider how the target audience will receive the product, how much it will cost, and what materials will be utilized in its construction. In addition, we want to consider how to make the product simple to package, keep, move, and repair.

Conformal coatings take up far less room inside a device's housing than PCB potting. The thin coating imposes little mechanical stress on the base. As a bonus, PCBs with conformal coatings are easier to rework, repair, and check.

Although conformal coating has a few drawbacks, it won't be as resilient or long-lasting as PCB potting. It may result in inadequate defences against devastating hazards. However, manufacturers that want to take advantage of conformal coating's benefits can choose from various materials.

YONGU CUSTOM DESIGN SERVICES

The term "modern industrial design" refers to a broad field that encompasses a variety of subfields, such as the design of products' functional aspects, structural aspects, forms, and packaging. Industrial design encompasses mechanical design, visual communication, architecture, interior design, environmental art design, furniture, product design, etc.

Industrial design involves thinking about more than just how something looks and works; we also have to consider how the target audience will receive the product, how much it will cost, and what materials will be utilized in its construction. In addition, we want to consider how to make the product simple to package, keep, move, and repair.

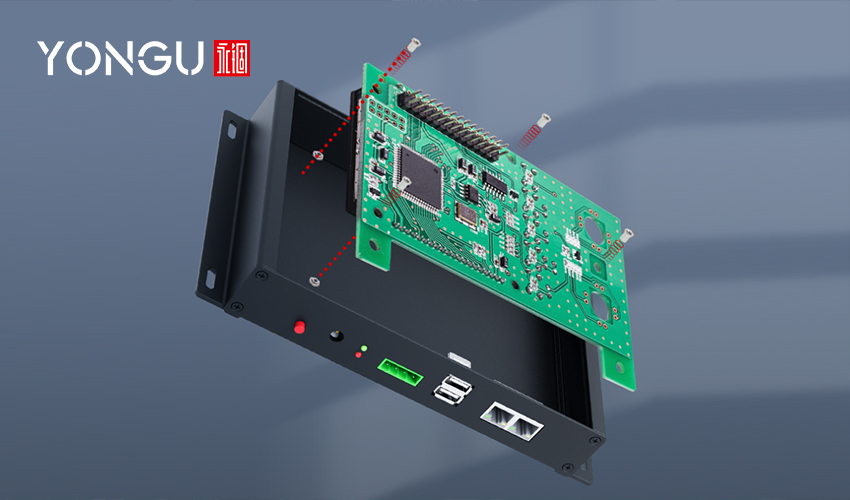

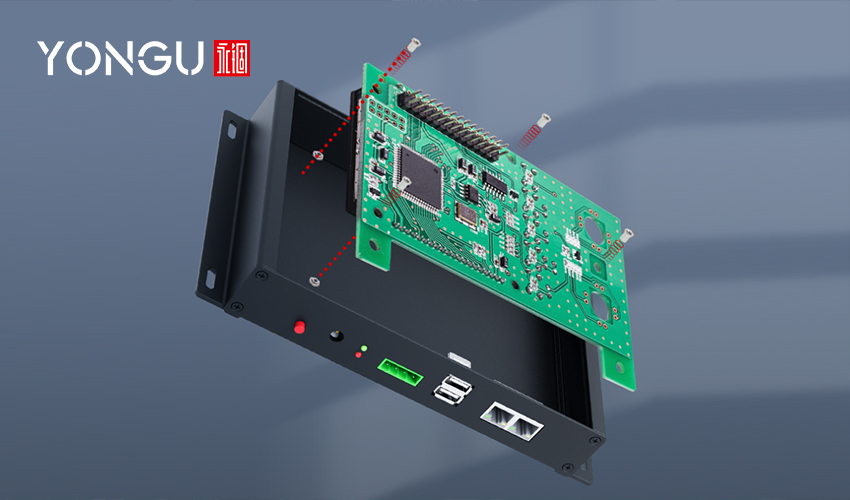

YONGU is an original design manufacturer (ODM) specializing in design and production, and the ODM items they produce are of outstanding quality. To help you realize your ideas and fulfil your needs, we provide comprehensive solutions for electronic enclosures, including all relevant areas such as look, construction, and function.

Our company is comprised of its manufacturing department, research and development department, and marketing department. We can offer a comprehensive custom design service and support electronic aluminum enclosures with any necessary revisions.

Engraving: CNC, UV, Silk Laser printing etc.

Making Cut-outs: Hole for Ethernet, Oled, Display, Fan, Power Jack, Led etc.

Other Hardware: Fasteners, Handles, Liner, Rubber Feet, PMMA etc.

Surface Treatment: Black, Silver, Grey, Blue, Red, Gold, Yellow, Green etc., via Anodizing and Powder Painting

Custom Other Function: Conductive, Non-Conductive, Passivated, Surtec and Alodine

For further information and customized product of your requirements, please follow our FACEBOOK for more updates and informations.Although conformal coating has a few drawbacks, it won't be as resilient or long-lasting as PCB potting. It may result in inadequate defences against devastating hazards. However, manufacturers that want to take advantage of conformal coating's benefits can choose from various materials.

YONGU CUSTOM DESIGN SERVICES

The term "modern industrial design" refers to a broad field that encompasses a variety of subfields, such as the design of products' functional aspects, structural aspects, forms, and packaging. Industrial design encompasses mechanical design, visual communication, architecture, interior design, environmental art design, furniture, product design, etc.

Industrial design involves thinking about more than just how something looks and works; we also have to consider how the target audience will receive the product, how much it will cost, and what materials will be utilized in its construction. In addition, we want to consider how to make the product simple to package, keep, move, and repair.

Conformal coatings take up far less room inside a device's housing than PCB potting. The thin coating imposes little mechanical stress on the base. As a bonus, PCBs with conformal coatings are easier to rework, repair, and check.

Although conformal coating has a few drawbacks, it won't be as resilient or long-lasting as PCB potting. It may result in inadequate defences against devastating hazards. However, manufacturers that want to take advantage of conformal coating's benefits can choose from various materials.

YONGU CUSTOM DESIGN SERVICES

The term "modern industrial design" refers to a broad field that encompasses a variety of subfields, such as the design of products' functional aspects, structural aspects, forms, and packaging. Industrial design encompasses mechanical design, visual communication, architecture, interior design, environmental art design, furniture, product design, etc.

Industrial design involves thinking about more than just how something looks and works; we also have to consider how the target audience will receive the product, how much it will cost, and what materials will be utilized in its construction. In addition, we want to consider how to make the product simple to package, keep, move, and repair.

YONGU is an original design manufacturer (ODM) specializing in design and production, and the ODM items they produce are of outstanding quality. To help you realize your ideas and fulfil your needs, we provide comprehensive solutions for electronic enclosures, including all relevant areas such as look, construction, and function.

Our company is comprised of its manufacturing department, research and development department, and marketing department. We can offer a comprehensive custom design service and support electronic aluminum enclosures with any necessary revisions.

The following specialized services and individualized designs and functional implementations are typically included in YONGU packages.

Custom Size: Width, Height, and Length can be changedEngraving: CNC, UV, Silk Laser printing etc.

Making Cut-outs: Hole for Ethernet, Oled, Display, Fan, Power Jack, Led etc.

Other Hardware: Fasteners, Handles, Liner, Rubber Feet, PMMA etc.

Surface Treatment: Black, Silver, Grey, Blue, Red, Gold, Yellow, Green etc., via Anodizing and Powder Painting

Custom Other Function: Conductive, Non-Conductive, Passivated, Surtec and Alodine

You can also contact us at +86 13326782625 or write us [email protected].