Condensation occurs when water droplets from humid air condense onto a cold surface. The presence of moisture and varying temperatures increases the likelihood of this happening in the natural environment.

Electrical enclosures face a significant threat from the formation of condensation. Consider all potential environmental concerns when selecting an electrical or electronic item enclosure. Because it might allow moisture to enter an enclosure, condensation must never be ignored.

Outdoor enclosures are particularly vulnerable to condensation during the unpredictable weather that characterizes the Spring season primarily. If the humidity level inside is too high, condensation might form.

When humidity levels are high, even a minor temperature drop might cause condensation within the storage unit.

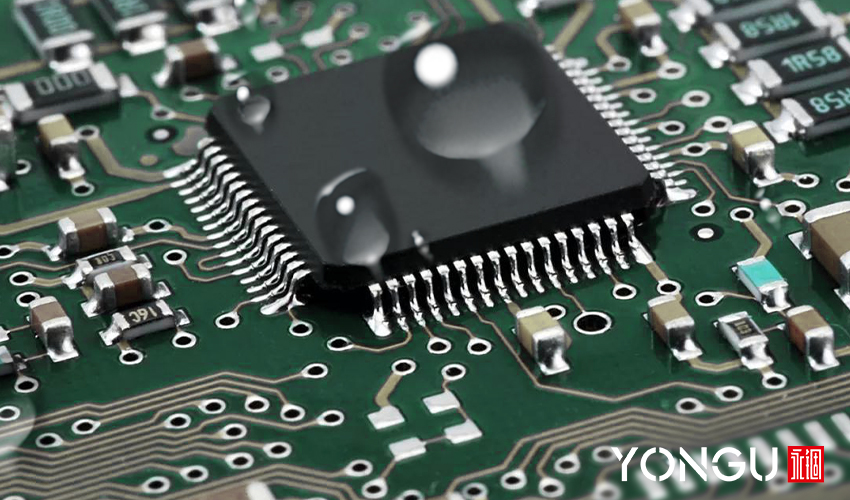

EFFECTS OF CONDENSATION ON ELECTRONIC AND ELECTRICAL COMPONENTS

It can have a wide range of effects on electrical and electronic components housed in enclosures.

- The components' performance degrades over time due to condensation.

- There may be an increase in resistance in the components, as a result, leading to overheating.

- Impure water carries electricity; there is a possibility of a short circuit.

- Rust forms over time as a result of corrosion brought on by moisture. The metal enclosure meant to shield the components might potentially rust.

CONDENSATION PREVENTION AND REDUCTION WITHIN ELECTRICAL & ELECTRONICS ENCLOSURE

Most commonly, these techniques are utilized to cut down on condensation drastically:

Circumventing Temperature Fluctuations

Locate the outside cabinet enclosure in an excellent, shady spot, far from any sources of heat that may cause moisture to build up.

To a lesser extent than metal, plastic enclosures can prevent heat transfer and provide superior insulation. Plastic enclosures can adjust to changing air temperatures more quickly, resulting in less condensation when the ambient temperature fluctuates rapidly.

In addition, enclosures should be kept from water sources since steam might be a problem.

Mounting Air Conditioning & Ventilation System

Condensation may be prevented by improving the ventilation of electrical enclosures.

The machinery inside the enclosure will generate heat, which might cause issues if the enclosure does not allow enough air circulation. Overheating of the apparatus is another issue in addition to condensation.

Vents in the electrical panel can solve this issue. Crossed ventilation maintains a constant, comfortable temperature inside by bringing in cool, fresh air from the outside and venting warm, stale air from the inside.

While it's more cost-effective to use natural ventilation in an electronics enclosure, forced-air ventilation that uses mechanical methods is more effective. Blower fans circulate and cool the air inside the enclosure, which is how condensation-reduction systems work. Because of the high temperatures, forced air is often necessary for large, high-input power equipment.

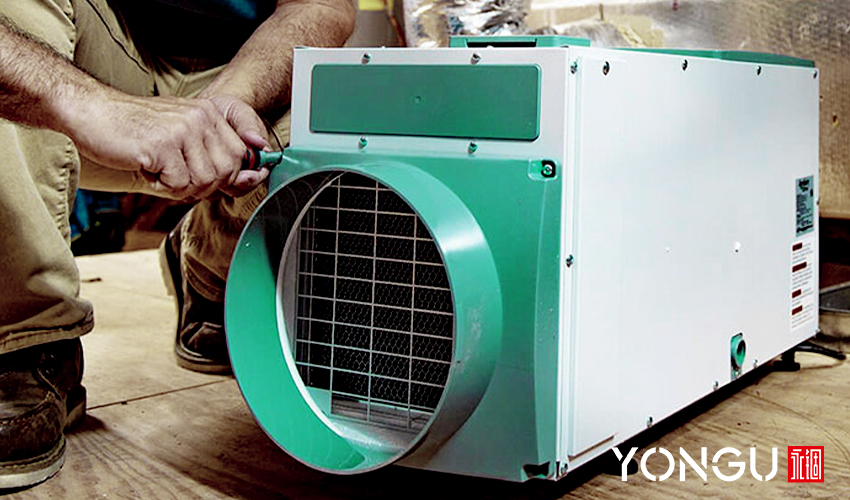

Setting Up a De-Humidifier

A dehumidifier for enclosures should be used to prevent moisture damage to sensitive electronics. Quite a few variants exist. An example is a dehumidifier, which uses a tiny fan and a refrigeration coil to remove moisture from the air. It makes the air more saturated with water vapour, which in turn causes condensation on the coils. The water is eventually collected, Dripping into a pan, bucket, or pipe outside the enclosure.

Besides mechanical dehumidifiers, electronic models are available for electrical cabinets. The Peltier effect transmits heat to a cold surface, causing the water vapour in the air to condense. A bucket or pipe must be set up similarly to the first choice if you want to collect the water. Another kind uses electrolysis to remove moisture from the air without water. Here, we employ electron flow to split water into its component gases, oxygen and hydrogen.

Infrared Heater

It should be a humidistat-controlled heater. When the weather outside drops, the air within the structure also begins to feel cooler. The atmosphere is weighed down to the point of saturation by water. The humidity in the air will begin to condense if the temperature within the enclosure falls below the dew point. When the relative humidity inside an enclosure rises beyond a certain threshold, a humidistat activates the heater to keep the temperature from falling below the dew point.

Dry Nitrogen and Silica Gel

During production, dry gas purges the enclosure of all breathable air, leaving behind a dry, inert atmosphere. Dry nitrogen is used to eliminate moisture from sensor systems and lessen oxidation effects.

Desiccant (such as Silica Gel) absorbs and retains moisture at minimal cost, but it must be checked frequently. Workers must be mobilized to the location when replacement is essential due to saturation.

CONCLUSION

Electrical enclosures require special consideration when installed in wet environments, such as those near the ocean, areas prone to heavy rain, places prone to dramatic temperature swings, or areas with extremely high humidity.

Problems of this nature may be avoided with the help of adequately installed electrical junction boxes and accompanying accessories, leaving more time and resources available for other operational tasks.

It becomes more challenging to drain moisture from the enclosure as the system's IP rating rises. It means enclosures with a lower IP rating need less ventilation because air is already leaking through the gaskets and other leak spots. The ventilation solution is even more crucial when it comes to enclosures with a high IP rating.

YONGU IP68 WATERPROOF ALUMINIUM BOXES

YONGU IP68 Waterproof Aluminum Enclosures are designed for use in harsh situations, such as those found in applications that take place underwater or outside. As a result, they are a fantastic option for usage as outdoor enclosures in all of the environmental conditions discussed previously.

YONGU provides customers with diverse IP-rated enclosures that may be modified in various ways to meet their specific needs. If you are interested in IP68 enclosures, we are happy to supply a range of kinds, some of which are listed below:

- YONGU L Series

- YONGU M Series

L Series includes around 24 models with robust enclosures that may be used in any environment. In comparison, M Series include around 11 different models with Highly versatile enclosures at an economical price.

They have the following common properties, including

For further information and customized product of your requirements, please follow our FACEBOOK for more updates and informations.

You can also contact us at +86 13326782625 or write us [email protected].

They have the following common properties, including

- Robust and durable for heavy-duty use

- Using a distribution ring makes it easier to maintain waterproof and dustproof functionality.

- Resistant to shocks due to die-cast aluminum housing

- Conductivity may be achieved by using the unpolished interior surfaces

You can also contact us at +86 13326782625 or write us [email protected].