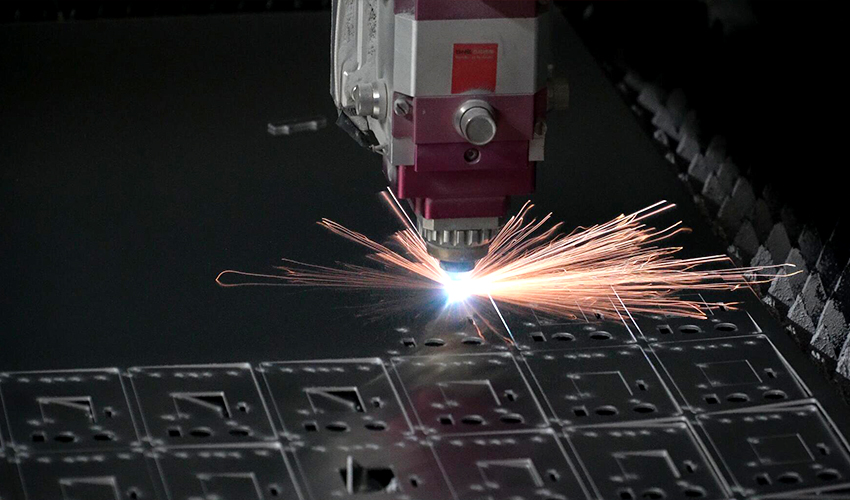

A laser cutter is a computer-programmed machine with highly focused and highly amplified light. It produces precise cuts or engraved materials using a laser beam. The laser beam makes the material burn, melt or vaporize. Depending on which type of laser to use, rely on the kind of material to cut.

Do you know what laser means? It's an acronym that stands for Light Amplification by Stimulated Emission of Radiation. The development of the first laser technology was in the 1960s.

Lasers cutting have varied purposes. We can use it for cutting holes into sheet metal plates. The laser cutting process is highly accurate

on mild steel, stainless steel, and aluminum plate. It yields excellent cut quality. It has a small kerf width. Its minimal heat effect zone makes it possible to cut very intricate shapes and small holes.

How does a laser cutting machine work?

The first thing to consider before using a laser cutter is your design.

Considering the size of your material or the maximal size that the laser bed can accommodate is also very important. Define the maximum dimensions of your design. Set the color mode to RGB. Different colors have specific processes. For example, red is for all the parts while black is for engraving. Once you have these, you can now use the laser cutter.

Like most machines, a laser cutting machine is also potentially dangerous. Safety first is the key. Make sure you spend time reading and understanding all the safety instructions. The wavelength of a CO2 laser is in the infrared part of the light spectrum, making it invisible to the human eye. You might get confused with the red dot you see with many machines on the material surface. It is just a positioning aid and not the laser beam that does the cutting.

What advantages does a laser cutter have?

- Stress-Free Cutting: A laser cutting machine need not have other tools to work on metals. It removes microscopic fractures and stress marks as these weaken a piece of metal sheets.

- Extremely Close Cutting: Because laser cutting is stress-free, it allows to cut metal shapes extremely close together. Creating metal cutouts becomes practical and forms more metal shapes from a single sheet.

- Smooth Edges for Cuts. Lasers can cut sheet metal forms that leave behind a smooth and shiny surface. It reduces the risk of having sharps or burrs left behind.

- Minimal Tooling Wear. A laser cutting machine has no physical contact with the workpiece. It makes lesser wear-and-tear on the laser cutter than on bending equipment or press brake. The life of the laser cutting machine extends and reduces maintenance costs.

- Less Need for Secondary Operations. The need for secondary operations to remove sharps and burrs decreases because of its smooth cuts. It increases manufacturing speed. You can have manufacture more parts in a day.

A maker describes a laser cutter in three things: precision, repeatability, and speed. Set your design and your settings. Surely no regret when using it because you will see your products with exact copies of the same piece.

YONGU is using laser cutting technology to produce high-quality products. With our expertise and the latest technology, we can guarantee customer-friendly and excellent services. Contact us and let’s make your project possible.