Making electronic enclosures for your electronic use is a new trend in the electronic field. The designed electronic enclosure could perfectly protect and house your products. However, what should I notice when I design an electronic enclosure? You are on the right page! This post will guide you through the design concepts and different kinds of material.

Design Concepts

Although you may think you have already known about what your electronic enclosure should look like. However, it is a challenge to realize your dream electronic enclosure. To make your product work well in your new design housing box is another challenge.

Making customization enclosures can run the gamut from making a simple box housing for the electronic parts to elaborate the contraptions. When you are making a box project, you have to consider different details. You have to carefully observe the size and shape of all components.

Also, you should consider how these components can be normally placed in a limited enclosure. Furthermore, you need to determine how the end-users will access sensors and power.

You may get freaked at first, once you know you have to consider many frustrating aspects. Don’t worry. We are here to help you design your electronic enclosures. Let’s start our journey of making our electronic enclosure design and overcome the difficulties that we encounter in the making process.

Space & Routing

The space of the enclosure is the first and the most important thing we should consider when we begin to design the electronic enclosure. No matter how fancy you design the enclosure, the electronic box is not big enough to house the all components and PCB parts, which means this box is useless.

But how to make a reasonable arrangement for all components? Here is the solution. First, you lay out all electronic components on a flat surface and arrange them until the configuration makes sense. Second, you determine how much clearance can you get away with above and below the PCB to calculate exterior dimensions.

Even if you are plan to design an enclosure to house one capacitor, you also should calculate the effective interior size in case to make some adjustments.

Internal Mounting

The internal mounting directly affects the working of the circuit. Therefore, you need to find out a reasonable and effective circuit route to prevent shorting or loosely jumbling. You had better secure each component in some ways to make sure all components will not be a mess on any occasion.

The most practical method to secure the PCBs and other flat components is screwing them into the box house. You also could learn some pre-made boxes, making grooves along the walls to make the PCBs or components easily slide in and out.

Accessibility

After making a great layout of the component, you may simply think the circuit route and components would be secured forever. Wrong! Even if a perfect arrangement, it still face the possibility of loosing. Therefore, we should take the possibility of enclosure parts must be accessed and how the user how to reach these parts and components into consideration. This consideration would help each user easily to fix the internal circuit route and the place of PCBs.

Choose the Right Material for Your Box Project

Each material has its pros and cons. The right material of housing box could correctly protect your internal components and PCB board. The material of electronic housing boxes is divided into two types: plastic, metal.

Plastic Project Box

Compared with metal enclosure, the plastic gives good performance in cost and durability. Therefore, plastic is a relatively more affordable and practical material. With the advanced plastic technology, plastic can offer you a variety of colors to select, to fit your specific color need.

What is Plastic Enclosure?

Plastic enclosureare used for housing and protecting electronic and electrical components. It the most popular non-metallic material in making enclosure or box. The Plastic enclosure is relatively great equipment in the electronic market.

What is ABS Plastic Enclosure

ABS(Acrylonitrile Butadiene Styrene) is a more advanced plastic. It is a relatively tough thermoplastic. ABS plastic can be welded together with normal acetone for permanent, to form a durable plastic enclosure. ABS plastic is widely used for 3D printed products.

How to Make a Plastic Enclosure?

The making procedure of the plastic enclosure is the manufacturer firstly heat the plastic until be liquified, or molten. Then the plastic is fabricated via molding.

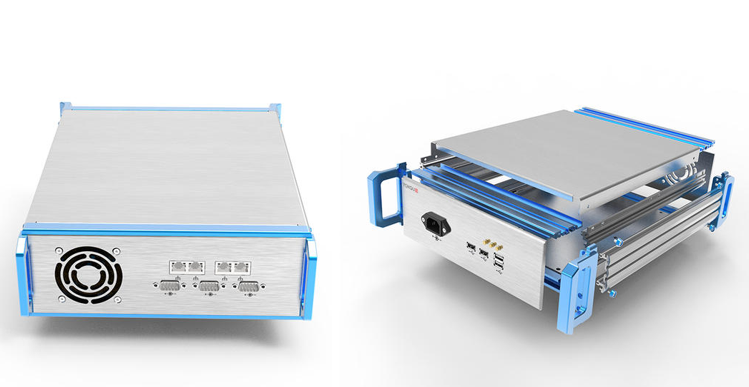

Metal Enclosure & Box

The metal enclosure is the most expensive housing solution, but its price is worth it. It makes excellent performance in reliability. Furthermore, the metal enclosure provides a practical benefit that is quality RF shielding.

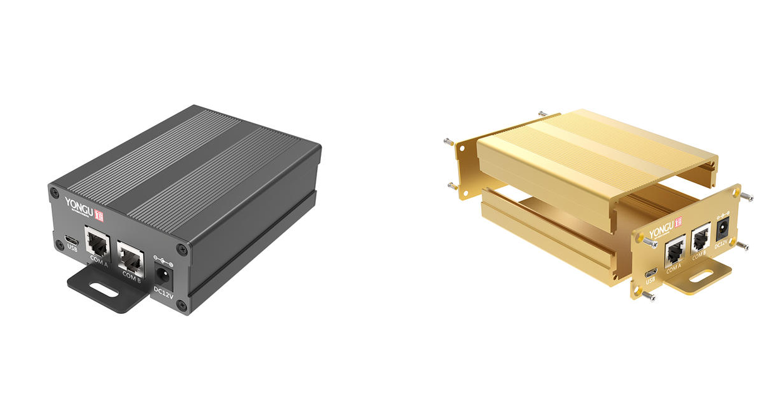

Aluminum Enclosure/Box

An Aluminum enclosure is the most excellent material for the enclosure. The aluminum allows manufacturers to use different technology. When you choose Aluminum as the material of your PCB board box, it can be anodized, colorful dyeing, and laser engraved. During the manufacturing process, it also can be bent and cut. Nowadays, the extruded aluminum enclosure is the favorite in the field of the electronic enclosure, with its outstanding features.

Stainless Steel

Stainless steel is a great material with its high durability, making great performance in scratching, pitting, staining, and corrosion resistance. In addition, stainless steel has different grades to meet specific needs. Take an instance, the 316 stainless steel has great resistance to chemicals and chlorides (like salt)

What is a Sheet Metal Enclosure?

When comes to the topic of the metal enclosure, sheet metal enclosure can not run out of the topic. The sheet metal means the manufacture cut the metal as a sheet, then they assemble couples of sheets to form an enclosure. If you want to get the sheet metal enclosures, you have to find the factory that offers custom-fabrication. They are simple but require high manufacturing technique.

Custom Electronic Enclosures

As mentioned above, custom electronic enclosure! A Custom electronic enclosure is the other practical and great solution to make your electronic enclosure and box. If you find a trustworthy custom electronic enclosure manufacturer, you don’t need to worry about too much. Only if you describe your ideal enclosure or box to the engineer in detail, you could get your great and scientific electronic box or PCB housing box.

Conclusion

After reading this ultimate guide, you may get some inspiration about making your electronic enclosure, circuit board enclosure. If you don’t want to get too much pressure from making an enclosure, finding an electronic enclosure manufacturers to get a customization enclosure is a great idea. YONGU s a professional intelligent manufacturer. Let’s customized service in YONGU!