When you are determining to purchase the customized aluminum boxes, you may have the hesitation whether I should mold design and make enclosure through the extrusion? You may also wonder what is extruded aluminum box and what’s the benefits of this aluminum enclosure? Today, this guide would give you a detailed introduction to enclosure extrusion.

What is Extruded Aluminum Process?

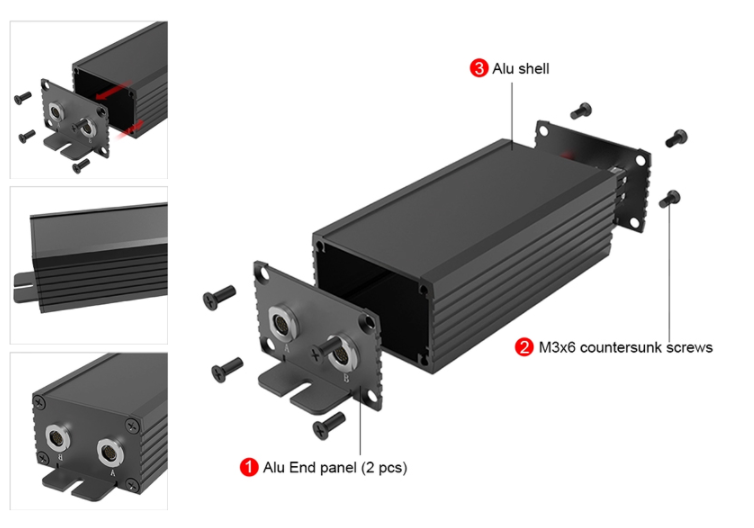

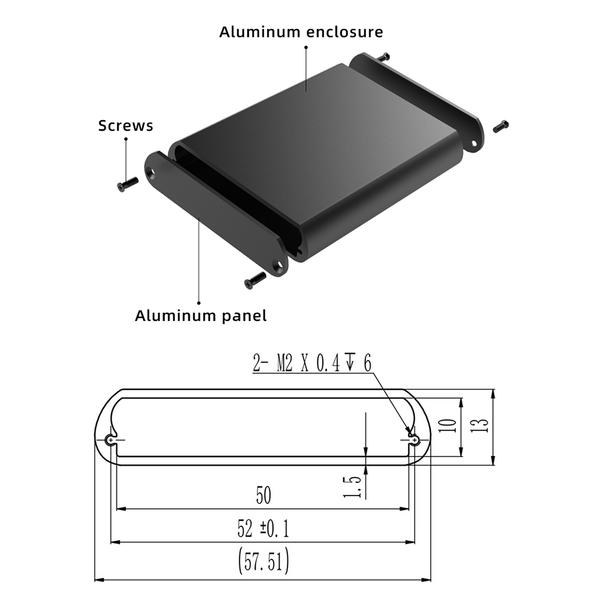

Extrusion is one of the processing methods that transforms the aluminum alloy into shapes with a definitive cross-sectional profile for versatile uses. Taking advantage of the physical features of aluminum, the aluminum extrusions can be applied to the architectural, marine, especially to electronic enclosure fabrication.

What is Extruded Aluminum Used for?

As above mentioned, relying on the stable features of aluminum, it can be used in a variety of applications. It can be used in architectural millwork, solar renewable energy industries, bridge decking, especially in electronic enclosures.

The Benefits of Aluminium Extrusions Electronic Enclosures

Compared with other fabricating technologies, extrusion aluminum provides many distinct benefits, including corrosion resistance, high strength-to-weight ratio, great strength, and so on. But what do these benefits mean for the extruded aluminum box? What the user can benefit from this PCB aluminum box? Let's look at the following parts to solve the above confusion.

Great Performance in Various environment

The extruded aluminum project box does a great job in all different environmental conditions. Because the aluminum is UV stable, the box will stay in solid form under the sunshine and protect some PCB components from harsh sun rays.

Effectively Prevent Interference

The one-piece aluminum enclosure takes an effort on preventing radiofrequency interference(RFI) or electromagnetic interference(EMI). Furthermore, aluminum has great ability on absorbing signals, so that it could prevent the signals from the sensitive internal PCB components.

Support Customized Design

High ductility, high strength, and good stability both allow enclosure manufacturers to provide customized aluminum box service. It is easy to form, extrude, and machine into complex shapes. That means you could list the specific structure or a completed sketch design of the aluminum enclosure box to your manufacturer to produce the ideal and perfect electronic enclosure.

Excellent Durability

Combining with the extrusion technology, the aluminum ensures the aluminum enclosure box is more damage-resistant and thicker than the normal roll-form aluminum.

Conclusion

All in all, extrusion is a great technique for aluminum, because it not only presents the advantages of aluminum to an extreme but also provides humans with great extruded aluminum enclosures electronics in the electronic industry. YONGU is a professional extruded aluminum enclosure manufacturer. Our OEM enclosure and ODM enclosure could meet nearly any aluminum extrusion need our customers may have.

→Related Post←

Interesting Facts about Our Aluminum Electronics Enclosure

Interesting Facts about Our Aluminum Electronics Enclosure