As the world's manufacturing sector grows, there is a need for both new and more conventional forms of energy infrastructure. The smart grid is rapidly increasing the demand for electronics. Therefore, designers need to be familiar with the specific requirements of the energy business when choosing enclosures.

Here, we will provide a range of factors to think about when selecting enclosures for use in energy applications in order to assist in this essential decision-making process.

LOCATION

It's essential to think about where the enclosure will be placed. The quality of the materials and the level of security necessary for the product depending on its final location. The blades of wind turbines, for instance, can be adjusted via unique mechanisms.

Outdoor application necessitates the equipment conforming to a strict set of NEMA standards. NEMA 4 or IP equivalent enclosures are ideal for use in outdoor settings; however, NEMA 12 enclosures may be suitable under some circumstances.

In less exposed areas, where the worst that could happen is a drip of water, a NEMA 12 enclosure would be adequate. Experts advise using stainless steel because of its corrosion resistance, strength, and longevity in supporting the equipment.

CAPABILITIES OF ENCLOSURE

You must understand how vital it is. An enclosure with mounting bosses can significantly aid in maintaining the box's integrity and speeding up installation when attaching a printed circuit board. Mounting panels that fit into the base of the enclosure are ideal for speedy installation when a board is not the principal component or when multiple components are used. Control boxes are placed on other pieces of machinery or on walls to protect them from accidental dropping. Brackets on the box's sides or built into the enclosure makes this operation much more effortless.

In addition to installation factors, there are a few other capabilities that should be taken into consideration, including the availability of enclosure accessories and the amount of internal space. Delivery delays can be problematic due to the modern emphasis on minimizing time-to-market. Purchasing managers should know that opting for a prefabricated enclosure can significantly reduce production time. If an enclosure of the correct size is unavailable, you should purchase a bigger one. The number of available suppliers can be expanded using an industry-standard enclosure size and design.

PREREQUISITES FOR APPLICATION

It's possible that the requirements of the application will influence the choice of enclosure. If, for example, the project requires intellectual property certification, having a box that is certified for IP makes the procedure significantly easier.

Aside from the NEMA ratings already indicated, EMI/RFI must also be considered. Removing the elements and electromagnetic radiation may be necessary for using solar power surplus. For applications like these, a die-cast aluminum enclosure that has a metallic inner sealing for protection against RFI and a silicon based outer sealing to prevent moisture infiltration is a good choice.

FOOTPRINTS

Future growth needs to be considered by designers alongside environmental safeguards. Engineers frequently make compromises in dimension when picking an enclosure. Although a tiny form factor is preferable in the present, if the enclosure is too small to house future components, it could cost a lot of money.

A further problem is a requirement for monitoring production. Consider using NEMA plastic enclosures with see-through lids if there are meters to be checked. The transparent covers prevent the requirement for cut-outs in the enclosure and the purchase of expensive NEMA-rated displays.

AESTHETICS & STYLING

When choosing an enclosure, aesthetics are an essential but non-technical consideration. Enclosure's aesthetics should be considered for a public setting like an office or a private setting like a house. The buyer decides on an enclosure's hues and construction materials to best advertise and win consumers over.

When it comes to their solar system, residential clients will only choose a control panel that has an industrial appearance. Given the importance of preserving the natural world, an uncluttered plastic box made to NEMA standards seems like the most sensible choice. Plastic has the ability to be molded into a variety of hues, which lends it versatility in the context of any design scheme. Even if the enclosure is meant for the factory floor, having a distinct visual identity for your product may help it stand out from the other similar products on the market.

CUSTOMIZATION

Customizability should be taken into account when choosing an enclosure. When a buyer doesn't factor in the possibility of enclosure changes, unexpected expenses may arise.

While some enclosures provide knockouts for cable access or other modifications, the vast majority must be customized to meet the installed devices' individual input/output needs. Depending on the specifics of the application, it may be necessary to make adjustments such as drilling new holes, cutting new slots, or applying silk screening, decals, or other customized finishes to accommodate specific pedagogical and promotional goals.

It is quicker and cheaper to have the enclosure provider perform the modifications because they already have the necessary tools and skills.

It would be best if you didn't wait until the last minute to decide on an enclosure for your energy application. A product's chances of being well-received by the market and its launch being pushed out unnecessarily are both negatively affected by the packaging it is shipped in. Choosing a suitable enclosure is the last piece to ensure a smooth product launch, but only if you pay attention to the other steps first.

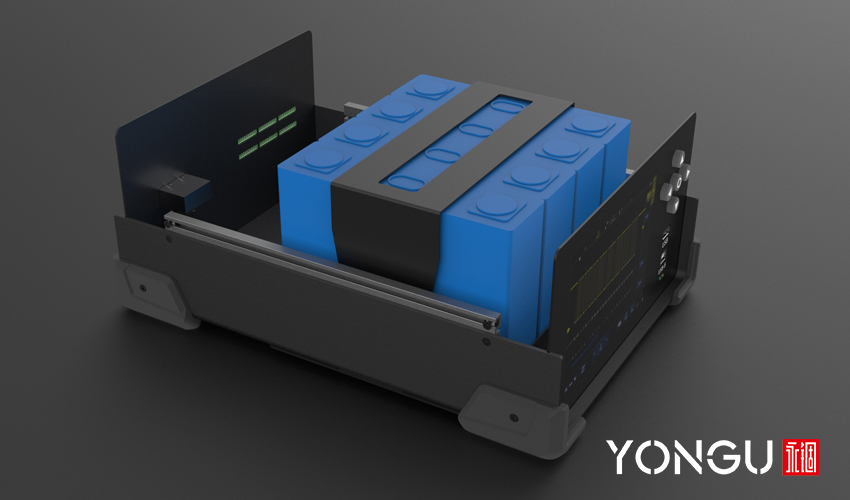

WEIGHT LOAD

Remembering that a dynamic load puts more force on a cabinet than a static load, even though enclosure weight-load capacities are often established in a static setting. Consider the weight capacity and limits of the vehicle while making cabinet strength and weight decisions, but give frame-channel construction and weld-joint design first billing.

When developing a dynamic application, the center of gravity is crucial, but it's less important in a static setting. A cabinet's stability and efficiency are compromised by its increased propensity to tilt and topple if its center of gravity is too high. As a result, limiting the amount of time spent under a dynamic load is essential. There is no hard and fast rule regarding where a center of gravity should be; depending on the application, it may be necessary to place the weight below 30 percent of the cabinet height, while for another, it may be sufficient to place the load below 60 percent of the cabinet height.

SHOCKS AND VIBRATIONS

Test how much shock and vibration the electronic equipment can take before deciding on an enclosure solution for a dynamic environment. Finally, calculate the pulse, vibration, and G-level inputs for the shock and vibration.

Many stationary workplaces feature minimal movement beyond that created by internal equipment vibration and cooling fans, making the shock and vibration neutralization an easy task.

YONGU ENCLOSURES

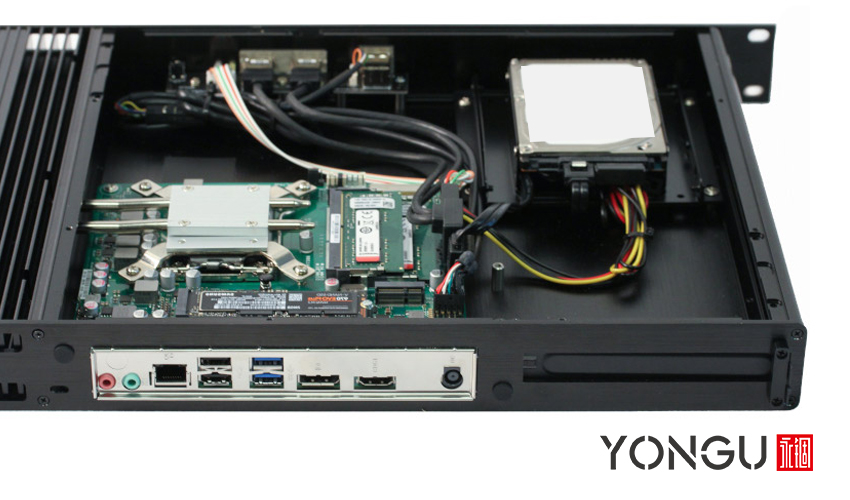

When it comes to electronic enclosures designed for application in industrial electronic equipment, YONGU has established itself as a global leader owing to its 16 years of expertise in the field. Includes a complete collection of aluminum and plastic enclosures ranging from simple housings to high-security versions that meet NEMA and IP regulations. Offers hundreds of commercially available enclosures in a broad range of sizes, shapes, and combinations. You can purchase a single case or buy them in large numbers all at once. Provides several customizable options to fulfill the requirements of individual customers.

In its manufacturing facilities, YONGU uses cutting-edge technology that is carefully calibrated to ensure the production of high-quality goods. They have achieved unrivaled success in the premium Hi-Fi business because of the ingenious production techniques and thorough quality assurance testing that they employ.

Among the many items available from YONGU are:

- Waterproof Enclosure

- Amplifier Enclosure

- Electrical Enclosure

- Instrument Chassis

- 19-inch Rock Mount

- Sheet Metal Bending Box

- CNC Box

For further information and customized product of your requirements, please follow our FACEBOOK for more updates and informations.

You can also contact us at +86 13326782625 or write us [email protected].