As a designer, you must choose the best enclosure for your needs so you don't waste money or time later on. So, choosing the right enclosure early in the design process could save money on design costs and time spent putting products together and reduce the number of product failures and claims. When choosing an industrial enclosure, the following information will help you make the best choice possible based on the highest possible impact rating and the longest possible lifespan.

What does having an IK-Rating Mean?

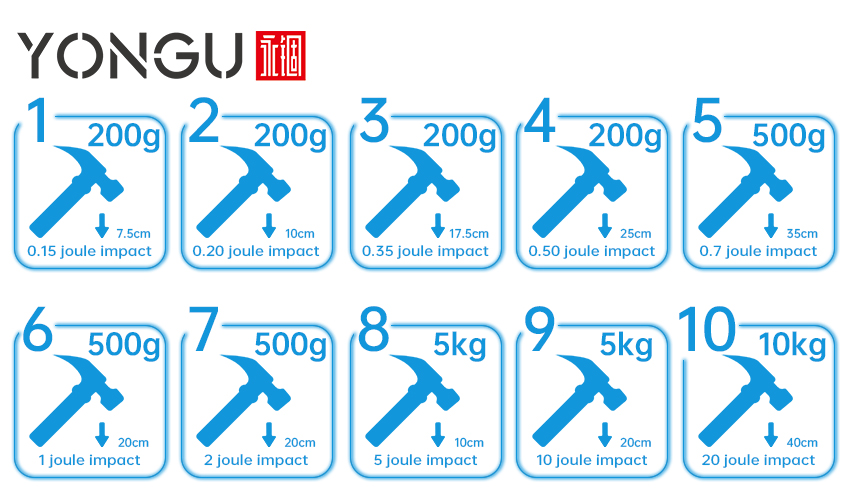

The impact resistance rating ranges from IK00 to IK10, showing how well a product can handle hits and falls. The more the IK rating goes up, the more the material can take being hit. Most enclosures meant for industrial use need an IK rating of between IK06 and IK10. Regarding industrial enclosures, third-party impact tests are done at temperatures ranging from -25 degrees Celsius to +35 degrees Celsius. It means that the item can be used in places where the temperature is both high and low. Plastic enclosures are harder to work with when temperatures are low because the material tends to get more brittle when exposed to cold.

Enclosure Testing

The enclosure is put through aging tests so that the effects of the environment can be seen. The enclosure is impacted in numerous ways to get a certain level of IK. After the planned strikes are carried out, the enclosure should work as it was meant to. The lab IK rating may tell you a lot about the enclosure's durability. On the other hand, the real-life criteria and situations might be different from what was tested. It is important to know how the product will be used to find the best solution that will last a long time.

Raise Your IK-Rating

Even though they are often seen on items created by manufacturers in other countries, IP enclosure ratings may be present on certain electrical cabinets built in the United States. To fully understand these evaluations, you must be aware of the potential that they might have two or three digits. These factors are focused on protecting solids, liquids, and impacts. The letter X is used instead of the number for certain devices with no specific rating.Material:

The first step is to use a material resistant to the damage that impacts can do.Thickness:

Make the enclosure thicker by adding more material to it.Form:

The shape of the enclosure should be made so that it either spreads the force of impacts over a larger area or absorbs the force so that it can keep moving through the structure.

A Low IP (or NEMA) Rating:

A lower IP (or NEMA) rating lets the enclosure bend more when it gets hit, but it still passes the test. It is because a lower level of protection goes with a lower rating. Because of this, a lower IP rating will also result in a lower NEMA rating.

Higher IK Rating

If you want an enclosure with a higher IK rating, you will almost always have to give up something. For example, you might have to pay more for the enclosure at first because it is made of better materials, or you might have to settle for a lower IP rating than you wanted. When making enclosures with a high IK rating, the raw material is the only thing more important than anything else. When constructing enclosures, stainless steel, glass-reinforced polyester, and polycarbonate are the three materials that perform the best. The most durable enclosures are those made of stainless steel.Among the available materials, stainless steel is the one that is the most costly but also the most resistant to being damaged. Even though it is very durable, glass-reinforced polyester can't be recycled and can be damaged by UV light.

Since technology has changed recently, polycarbonate can be in this group. Because of these steps forward, it was possible. Polycarbonate is a matter that can be recycled, doesn't rust, and doesn't break down when exposed to UV light.

Most of the time, increasing the thickness of the walls of an enclosure can make it last longer. Corners are often the weakest parts of a building, so circular shapes can help move impact energy away from the building or spread it out over a larger area.

It is why circular shapes are stronger than other shapes. When it comes to being able to take hits, a case with rounded edges often has a better chance of doing so than a case with sharp edges. It is because sharp edges are more likely to break when they hit something hard.

Which standard YONGU follows?

With regards to standards, Yongu provides enclosures that conform to IP67/IP68. Check out our article on IP rating for more information.Heavy machinery, industrial plants, and underwater and outdoor applications require IP67/IP68 enclosures. We would recommend using YONGU enclosures as they have a wide variety of IP-rated enclosures with flexible customization options. These enclosures come in two series: L and M series.

Or our anti-collision aluminum enclosures, K series. For more protected informations.

YONGU L Series: Durable enclosures rugged enough for indoor or outdoor applications. L Series include around 24 different models, including

- Outdoor Electrical & Water Proof Boxes

- Waterproof Plastic Enclosures

- Waterproof Electrical Enclosures

- IP67 Aluminum Boxes

- Waterproof Electrical Junction & Power Boxes

- Weatherproof Electrical Enclosures

- Waterproof Metal Junction Boxes

- Waterproof Box for Boat

- Waterproof Battery Boxes

- Automotive Waterproof Electrical Junction Boxes

- Waterproof Connection Boxes

- Waterproof PCB Boxes

- Waterproof Switch Boxes

- Waterproof Underground Electrical Junction Boxes

M Series include around 11 different models, including

- IP67/IP68 Aluminum & Waterproof Boxes

- weatherproof electrical boxes

- outdoor electrical junction boxes

- waterproof junction boxes

- outdoor electronic boxes

Both M and L series have the following properties in common.

- Rugged and robust for heavy-duty use.

- Maintaining waterproof and dustproof functioning is made easier by using a distribution

- Dispensing ring

- Diecast aluminium housing that is resilient to socks

- The unfinished interior surfaces can be used to achieve conductivity

Conclusion

You must think carefully about how the product will be used, paying special attention to whether or not it will be used roughly or hit. To meet your needs for a longer performance, you should make it a point to research to find out which product is the best deal in terms of price and quality. Considering the environment where a product will be used when installing it is important. When you take everything into account, each of these different parts will have some effect on how well your product works. Ultimately, you should choose a strong device that lasts long, protects your integrations, and saves you money simultaneously.For further information and customized product of your requirements, please follow our FACEBOOK for more updates and informations.

You can also contact us at +86 13326782625 or write us [email protected].