Switches, fixtures, and outlets all have connections that need to be shielded from the elements, tampering, and other potential disruptions to their operation by being housed in electrical boxes. Whether you need one for an indoor or outdoor installation, you can choose from various styles of electrical boxes. In order to prevent fires and electrical shocks, electrical boxes must be installed in every residence. There are ceiling fans and heavy light fixture-specific boxes, as well as round, square, and octagonal ones; plastic ones; and metal ones.

SELECTION BASED ON MATERIAL

Strong & Safe Metal Boxes

Steel is the material of choice for metal containers. Aluminum is a common material for outdoor storage containers since it is both inexpensive and durable. A metal electrical box is necessary if a metal conduit is used to bring wires to the box, both as an anchor for the conduit and as a potential grounding path for the system. Metal storage containers last longer, are more secure, and can't catch fire.

Plastic Electronic Boxes

PVC and fiberglass are the two most common materials for making plastic containers. In addition to being more cost-effective, plastic containers with built-in clamps for cables are widely available.

SELECTION BASED ON STRUCTURE

Single-Gang or Rectangular Boxes

A standard rectangular box is used with a single light switch and outlet receptacle. This box type is called a "single-gang" or "one-gang" box. Some designs are gang able, meaning that their sides can be removed to create larger boxes that can house two, three, or more devices side by side.

Standard rectangular boxes can be found in a wide variety of "new work" and "old work" designs and can be made of metal or another material (with metallic being more durable). Built-in cable clamps are available on some models for securing NM cables. The price of these containers might differ, although the more common ones are cheap.

Round Pan-Shaped Electrical Junction Boxes

Pancake choices, sometimes known as round pans, are shallow circular containers typically used for light fixtures weighing less than 50 pounds that are installed on the ceiling or wall. These electrical boxes are shallow; they can only accommodate a couple of plugs.

Octagon & Round Boxes

Octagonal and standard-size round boxes are the go-to for light fixtures up to 50 pounds that will be placed on a ceiling or wall. In addition to their usefulness as junction boxes, their larger size makes them a better option for wiring than shallow circular pan boxes.

Square Electronic Boxes

Standard depths for square boxes range from 1 1/4 to 2 1/8 inches, but the extra volume created by their square edges means you can fit more wires and connectors inside.

When paired with the appropriate cover plates, they can serve as junction boxes installed in the ceiling or wall to hold lighting fixtures, switches, and receptacles.

Junction Boxes

To contain wire splices, an electrician typically uses a junction box, which is not a distinct box type but a generic phrase.

The typical junction box is a 4-inch square box (often made of metal or sturdy plastic) that provides ample room to establish wires with several wires or cables. The cost is different for each possible junction box configuration.

2, 3, and 4 Gang Configurations Electrical Junction Boxes

These three varieties are compatible with standard wall outlets and switches, but they're enlarged so that up to four electronic gadgets can be used at once. They also come in both vintage and modern variations. Some of them have cable clamps built right in.

Outdoor Boxes

Both plastic and metal models are available for outdoor boxes and are suitable for various uses. Sealed seams, gaskets, and waterproof covers are typical in these to shield wiring and circuitry from the weather.

The New and Old Work Boxes

Old-work boxes, also known as remodeling boxes, have built-in clamps that allow them to be hung from pre-existing drywall. After drywall has been placed, they should be installed. Mounting new work boxes directly to joists or studs is the standard installation method. These wall outlets are made to be hung from a bar during the building process.

FACTORS FOR EVALUATION OF THE RIGHT ELECTRICAL BOXES

Although many different types of electrical boxes exist, each must be put to its appropriate use, so the following factors must be considered.

Evaluating Volume and Setbacks

An enclosure's total volume is the amount of room available inside the enclosure for installing cables and other electrical components. The setback of a box specifies the distance that its front will be set back from the wall. This is something to consider if you're planning on installing tile or another dense wall covering. The width of a box and the maximum number of outlets, switches, and dimmer controls it can accommodate is measured in gangs.

Equipment for Joining Cables

Non-metallic-sheathed (NM) cable, conduit, and metal-clad cable have specific electrical box designs. Many junction boxes designed for NM cable also include a clamp to secure the cable. Conduit and metal-clad cable boxes have partial, spherical knockouts of varying diameters punched out of the side. These types of junction boxes are compatible with NM cable as well. Attach the cable to the device with a certified NM cable connection.

Construction Materials for Indoor and Outdoor Use

Steel, PVC, fiberglass, and cast aluminum are some of the most frequent materials used to make electrical boxes. The material you should use depends heavily on the setting. If the container is used outside, ensure it can withstand the environment. Non-metallic-sheathed (NM) cable is best used indoors, and fiberglass is perfect for this. Indoor installations using NM cable and PVC junction boxes are recommended. Cast aluminum is your best bet if you need something that won't rust or corrode in moist or damp conditions.

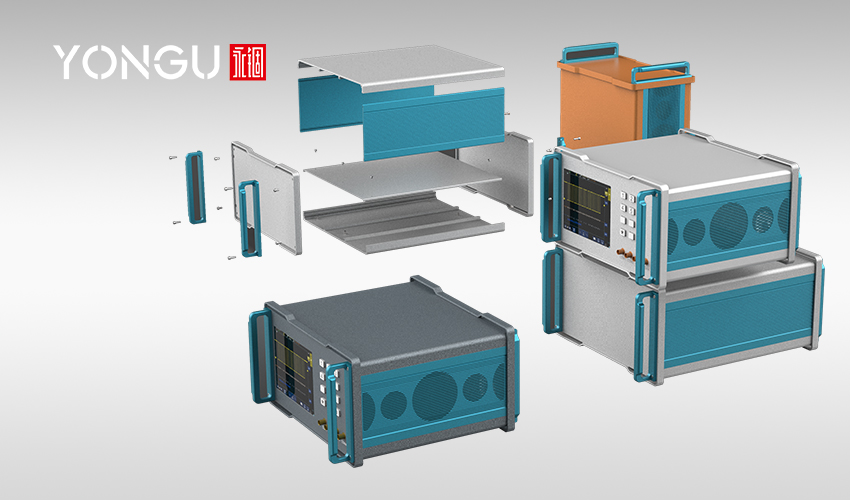

YONGU ELECTRICAL BOXES AND ENCLOSURES

Size, material, rating systems, and so on are just some of the many factors to consider while searching for an electronics enclosure factory to create a custom enclosure. Understanding the characteristics, advantages, and disadvantages of each material is crucial. Typically, our designers and engineers will choose the parts of the aluminum electric boxes based on the required specifications and the devices' purposes.

We are a leading maker of extruded aluminum and plastic electrical and electronics enclosures. Our company comprises three powerful groups: a design team well-versed in contemporary aesthetics, a skilled management team, and a quality assurance and after-sales services unit. Aluminum extruded enclosures that are both sturdy and aesthetically pleasing. Intended for usage in FA control boxes, networks, meters, and amplifiers. We offer a wide variety of portable, hinged, sloping, and flanged enclosures.

If you're working on an electrical or electronic project, YONGU provides the extruded aluminum electrical boxes you need.

YONGU electric box series includes three different models, including:

- One-piece structure box

- Split-type structure box

- Protected plastic end covers enclosures

These different models are being indulged in three different series, including

Plastic and aluminum enclosures are best for moisture-proofing printed circuit boards. Fully plastic-covered, partially plastic-covered with aluminum end panels, partially plastic-covered, and wall-mounted flanged waterproof enclosures combine both types of characteristics. ABS plastic tops and extruded aluminum housings. They're mobile, lightweight, and easy to install.

One-piece aluminum junction boxes made from al 6063 for the chassis and al 5052 for both the front and rear panels have high surface polish, oxidation resistance, welding capability, and anodization. All waterproof electrical enclosures are customizable.

They've split aluminum electronic containers. Aluminum alloys (al 6063 and al 5052) make them robust, durable, and ideal for demanding applications in several environmental conditions. Electrical enclosure customization includes colors, anodizing, sandblasting, and more.

You can also contact us at +86 13326782625 or write us [email protected]om.