TYPES OF PRESSURE SENSOR

It's important to note that pressure sensors come in a variety of forms. Transducers that measure pressure are also known as pressure transmitters and pressure switches.

Pressure Switches

A pressure switch is not a gauge but a device set to make or break contact at a predetermined pressure. Typically, pressure switches have a very short response time. They can be relied on and have a prolonged service life. Pressure switches are compact and inexpensive compared to other types of pressure-sensing technologies.

Pressure Transducers

When connected to a system, a pressure transducer can provide feedback in the form of an analog or digital signal that represents the actual pressure within the system. Unlike pressure switches, pressure transducers are more expensive but more reliable and durable. Pressure transducers can function in various environments and are resilient to dust and moisture. Pressure transducers are robust and precise enough to be used in various industrial and automotive settings.

APPLICATIONS OF PRESSURE SENSOR

There are a wide variety of uses for pressure sensors across several sectors.

- Mechanisms for Triggering Alarm

- Detecting Appliance Water Levels

- Home Brew Coffee Makers

- Appliances for Breathing Therapy in Medicine

- Robotics

- Automation

- Mechanical Refrigeration

- The Off-Road Construction Industry

- Agriculture

- Maintaining a constant eye on oxygen saturation

- Hydraulics in Industry

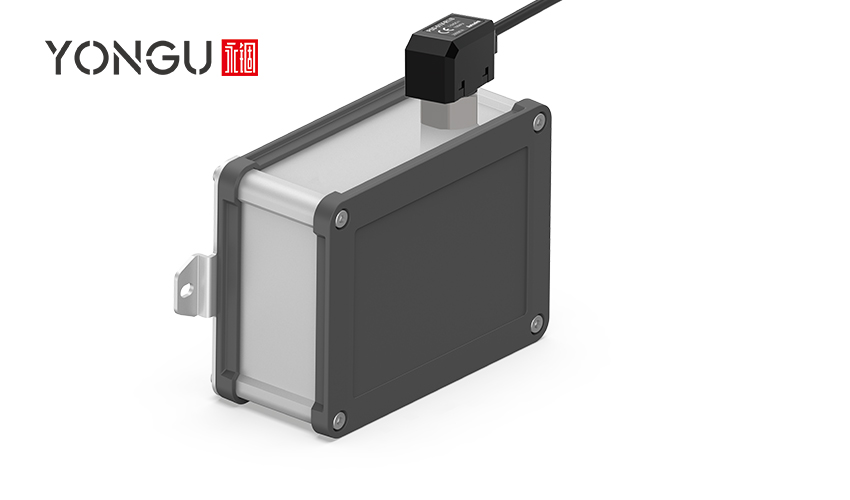

For vented gauge pressure transducers and transmitters, the Pressure Sensor Enclosure is a compact and durable enclosure that offers easy field termination. With an integrated micro-filter component, you can still use the barometer for reference while protecting yourself from dust.

The module housing a pressure sensor should be able to absorb water vapor from the air via capillary condensation and surface absorption. The enclosure should be made so that its replacement can be accomplished quickly and without special equipment.

PROTECTING PRESSURE SENSORS IN EXTREME CONDITIONS

Chemical Constituents

It's best not to combine substances that are chemically incompatible. When choosing to house your sensor, keep in mind that it must be resistant to any chemicals that might come into contact with the sensor and the application medium.

Consider what "normal" conditions are like. It is important to ensure that the entire sensor enclosure is compatible with any chemical concern, even if it is remotely possible that any other sensor parts will come in touch with the chemical.

Gradients in Temperature

Keeping the temperature comfortable can be challenging in extreme heat or cold. Whether purchasing a pressure transmitter, look for one that specifies a temperature range to assist you in choosing when to use temperature controls.

When you know the sensor's compensated temperature range, you'll know exactly where to use it. In other words, this is the margin of error within which the sensor operates normally.

The pressure transmitter's safe operating temperature range is the range in which the device can continue to work normally.

A pressure sensor can only be safely stored, not used, within its storage temperature range.

Remember that both the media and the ambient temperatures matter. Select the housing for the pressure sensor based on the requirements for the warmest possible environment. A heated enclosure may be required to keep the sensor operational in extremely cold environments. A standoff pipe and enclosure can be placed at a safe distance from the heater To protect the sensor from damage caused by high media temperatures.

Dust and Moisture

The reason NEMA and IP ratings exist is that moisture might cause damage to your sensor. The sensor's enclosure must have a good rating for the job. If not, you should keep it in a suitable enclosure.

In sufficient quantities, dust can potentially be dangerous. Dust protection is included in both NEMA and IP classifications. The first number in an IP rating indicates the degree to which the enclosure or sensor housing prevents dust from entering, while the second indicates the same for water. NEMA ratings are more complicated because they consider issues like ice, lubricants, coolants, etc.

It's important to keep in mind the airtightness of the container when dealing with drastic temperature changes. As temperatures rise and fall inside the enclosure, condensation will form. Use a dehumidifier cartridge and a vent with a watertight barrier to keep the enclosure dry.

YONGU SENSOR-COMPATIBLE ENCLOSURES

The following are characteristics of a standard pressure sensor enclosure:

- An IP68 rating is necessary for outdoor installation, ensuring resistance to corrosion, wind-borne dust and rain, splashing, and water from a hose.

- The material must be chosen to provide a structure that is both lightweight and extremely resistant to the effects of impact.

- Durability, safety, and ease of access to terminal connections can all be improved by designing the termination enclosure with rounded corners.

YONGU sturdy aluminum enclosures include improved heat dissipation and an IP67 or IP68 rating for dust and water resistance, respectively. Useful for sensors in both indoor and outdoor settings, including industrial facilities. Waterproof enclosures ensure complete safety. Wet environments and high-stress installations are ideal for this material. Most commercial and residential applications will be concerned with the IP68 waterproof rating of this electronic enclosure, and its strengths are detailed below.

The IP68 metal enclosure's superior waterproofing and sealing properties result from its one-piece silica gel seal ring. Waterproof to an IP68 standard thanks to well-designed seal screws. In addition, IP68 is the highest possible grade for enclosure and protects against dust and moisture.

Strong IP67 and IP68 metal enclosures with excellent heat dissipation. Fit for usage with heavy equipment, industrial machines, or the great outdoors

The aluminum enclosure has an ingress protection rating of IP68, making it ideal for use in rail travel, underwater detection, and outdoor monitoring applications. Electrical items with high ingress protection ratings can be used in harsh outdoor environments. Products that have been given the IP68 seal of approval are guaranteed to withstand the elements and function admirably in every climate.

The YONGU IP68 waterproof line includes the following two series. In particular, these characteristics should be noted.

- Official IP68 Waterproof Rating Document

- Adequate Sizing Flexibility

- Durable Enough for Regular Use

- Die-Cast Aluminum Enclosure for Impact Resistance

- Wall-Mounted or Deflated

- Assisting in the prevention of water and dust infiltration, the distribution ring

For further information and customized product of your requirements, please follow our FACEBOOK for more updates and informations.

You can also contact us at +86 13326782625 or write us [email protected].